While process simulation is not typically a mainstay of hospital planning, it is being used more frequently by organizations to better understand their systems. MOSIMTEC had the opportunity to work with a hospital that sought the creation of a future state resource schedule for their fast track system that best utilized the staff while caring for a high volume of patients.

The current process incurs around 250 patients per day and includes a 50 bed emergency center with 5 fast track rooms for patients with lesser acuity levels (a means of distinguishing the severity of a patient’s injury) . The first phase was the construction of the simulation model to determine the optimal system layout for the future state. In this phase the resource count was simply doubled with no change to scheduling, resulting in 200 man-hours per day. The goal of the second phase was to find the best schedule and staff count for the future state of the system.

The Problem and Approach

There are two main problems that MOSIMTEC needed to solve. The first was to determine the optimal staff count covering a 24 hour schedule. When resource optimization is a project goal, it is often obtained separate from the simulation via analytical means, i.e., it is calculated not simulated. Linear and integer programming in particular are tools for obtaining such analytical results.

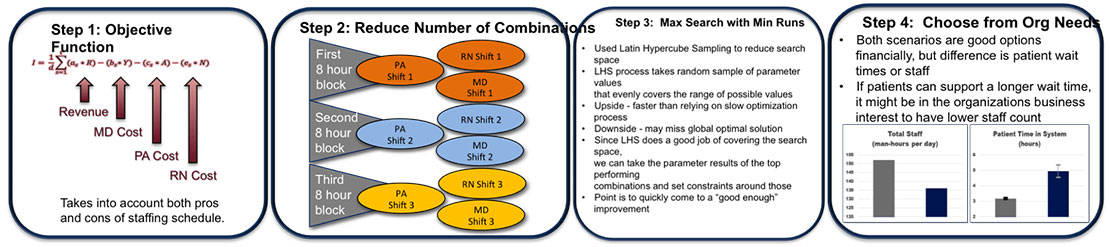

The challenges with using only analytical tools are two fold: (1) not being able to easily model a complex system of many components including their inter-relationships and (2) not being able to incorporate variability. Simulating a system can solve both challenges, but lacks the efficiency of quickly providing exact solutions because of the multiple iterations required. This led to the second problem, which was to create a methodology using the already created simulation model to efficiently obtain a solution. The methodology uses 4 stages to construct the model and complete the analysis. First, an objective function is generated. Second, heuristics, rules, and constraints are used to reduce the number of combinations. Third, Latin Hypercube Sampling is used to reduce minimize the number of runs in lieu of any third party optimizing software. Fourth, multiple best options are reduced based on organization need.

Result

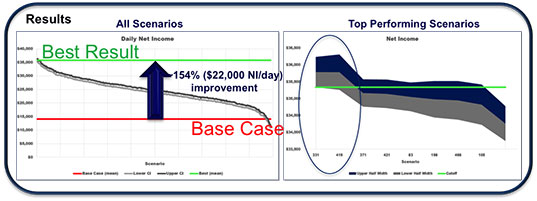

The results clearly show a daily net income for 500 scenarios that range from approximately $13,000 to around  $36,000. The base case using the original arbitrary inputs performed poorly relative to the other scenarios. The difference between the average net income for the base case and the average for the best case was $22,000 per day—an increase of 154%. Because this is a stochastic process that outputs a range of values, it is where the confidence intervals overlap that is of most importance. The top performing scenarios were reviewed where they overlapped the Lower Confidence Interval as seen in the figure below. Even though there are 7 scenarios that are above the cutoff, it is Scenario 331 and 419 that are the best performing configurations. These two scenarios at this point, however, are indistinguishable from the perspective of Net Income and were subsequently analyzed based on their patient waiting times and staff head count.

$36,000. The base case using the original arbitrary inputs performed poorly relative to the other scenarios. The difference between the average net income for the base case and the average for the best case was $22,000 per day—an increase of 154%. Because this is a stochastic process that outputs a range of values, it is where the confidence intervals overlap that is of most importance. The top performing scenarios were reviewed where they overlapped the Lower Confidence Interval as seen in the figure below. Even though there are 7 scenarios that are above the cutoff, it is Scenario 331 and 419 that are the best performing configurations. These two scenarios at this point, however, are indistinguishable from the perspective of Net Income and were subsequently analyzed based on their patient waiting times and staff head count.

About MOSIMTEC

The MOSIMTEC concept is different from traditional engineering and consulting services. It is based on the paradigm that technology will be instrumental in decision making. Sophisticated computer simulation software in combination with ever increasing processing speed and memory will enable decision support tools to deliver deep insight in a complex, dynamic, and real-time world. The MOSIMTEC team has extensive experience working with leading computer simulation software and solving complex issues for clients across various industries. We are uniquely positioned to support clients in making smart decisions by applying Modeling & Simulation Engineering (MSE) to predict outcomes, prescribe actions and improve operations.