Consider a simple Source-Server-Sink simulation model. In elementary modeling, values such as arrival rate and delay time would be hard-coded. In data-driven modeling, these model parameters would have been supplied by a data set.

Data-Driven vs Data-Generated Modeling

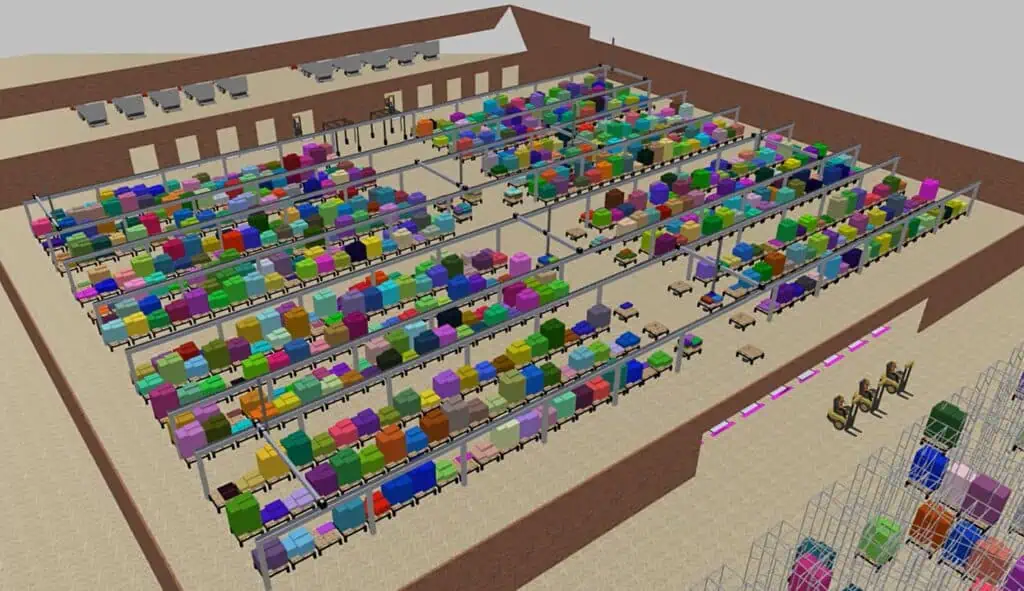

The next level in model sophistication is data-generated modeling. This is where the model starts out blank and objects are inserted at runtime via a dataset. In other words, objects, their type, and their position are user-defined inputs. This is beneficial because many operational sites can be simulated under one model.

Now consider this demonstration model consisting of work orders, workstations, and employees. This model represents production Site A. Originally, if the decision-maker wanted to model another production site, the modeler would have needed to make a separate model.

Data-Generated Modeling Benefits

With data-generated modeling, the site’s layout, so to speak, can have a respective input dataset. Now different operational sites can be simulated and compared in experiment runs.

The drawback to data-generated modeling is that process logic and object classes have to be generalized so that they can function under varying configurations, which can be challenging to implement. However, the obvious benefits to data-generated modeling might make the extra effort worthwhile.

Contact MOSIMTEC to learn more about developing data-generated models for your business.

MOSIMTEC’s core focus is assisting clients make better decisions through application of decision support tools. Our team has extensive experience working with leading computer simulation software and solving complex issues for clients across various industries.

Other Case Studies

- All

- 3D simulation

- AMR

- Anylogic

- automated mobile robots

- bottlenecks

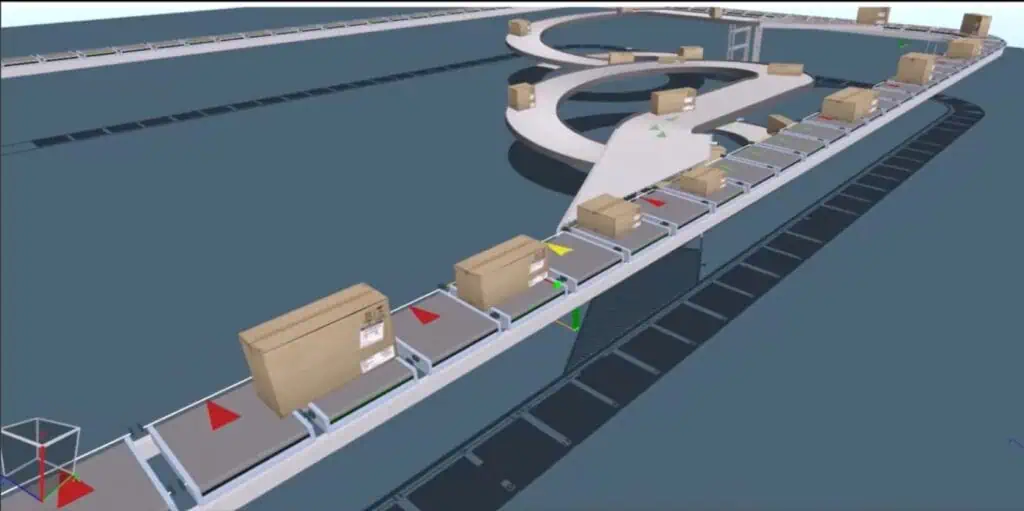

- conveyor design and implementation

- conveyor physics engine

- Distribution Center

- Emulate3D

- Emulate3D 2024 User Group Meeting

- industrial automation

- Logistics

- material movement analysis and design

- Oil-and-Gas

- order fulfillment

- Rockwell Automation

- Simulation

- slugging options

- terminal simulation

- throughput validation