Gain the MOST Insight into Real-World Production with MOSIMTEC Digital Twin Simulation

The journey to the MOST efficient business production processes begins with the BEST business simulation model – and that’s exactly what the experienced data scientists and industrial engineers of MOSIMTEC do every day.

Software-powered virtual model-based simulations (also known as Digital Twins) enable a company’s decision-makers to make better decisions. The reason is simple: Creating Digital Twins is the easiest way to see how your production processes are interrelated, so that you can determine which performance enhancements would result in improved efficiency.

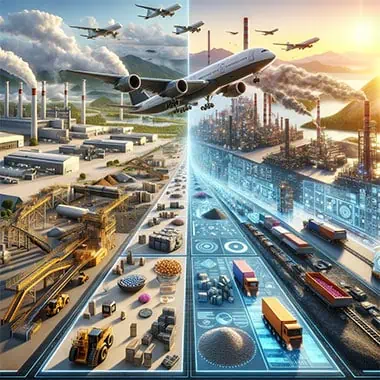

That’s how MOSIMTEC has helped airports, railyards, mining operations, manufacturing facilities, logistics and supply-chain providers, and companies in the pharmaceutical and healthcare industry be more efficient . . . thanks to an easy-to-understand digital view of your real-world systems – something known in the business simulation industry as a Digital Twin.

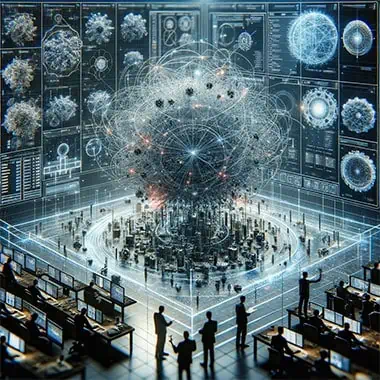

But what do we mean when we say “Digital Twin”? Simply put, the phrase “Digital Twins” means we create virtual representations of your entire processing system (including every asset and every physical object), then we run simulations of that custom-built model to ascertain which components can be adjusted to generate the MOST efficient processes possible.

To make a Digital Twin work for your entire product lifecycle, the experts at MOSIMTEC need to collect relevant data that accurately reflect how different assets, objects, and processes interact. By using real data of every actual physical asset, you’ll get the MOST useful digital model based on the MOST accurate data – and your journey is underway.

Let’s get started. Allow the professionals at MOSIMTEC to be your guide as we create a customized Digital Twin simulation model that truly replicates the real world – and genuinely gives your company an edge against your competition.

Partner With MOSIMTEC To Create Digital Twins That Boost Your Efficiency

The More Complex the Digital Simulation, the More MOSIMTEC Can Help

If you’re new to the concept of Digital Twins or if you’ve yet to work with Digital Twin technology, it can be a pretty daunting situation. A digital simulation of a company’s real-world production processes can quickly become exceedingly complex, with its series of inter-related systems all impacting the final result. There’s a reason powerful software is required to run simulations in the digital environment.

But there’s no need to fear the complexity inherent in building and running Digital Twins. In fact, the accomplished data scientists and industrial engineers of MOSIMTEC thrive most when tackling complex, complicated digital models.

That’s because the MOSIMTEC team is as well-versed in the needs of business as we are in Digital Twin technology. We want our clients to present us with challenging, complex problems – so that we can think deeper, think differently, and think ahead to solve them.

MOSIMTEC Is Your Guide To Better Decisions Using Digital Twins

Business simulation is a journey. Creating a useful model of business processes requires more than powerful software, accurate sensor data, and machine learning. It requires the expertise of experienced Digital Twin engineers.

At MOSIMTEC, we expertly guide clients on their journey toward the MOST insight using their custom-designed digital environment. As a guide, our role is to help clients avoid common pitfalls along the way to greater efficiency, and to deliver a final result that’s both applicable and implementable.

MOSIMTEC is your partner on the journey to impactful Digital Twin business operations simulation. Depend on our experts as your guides to deeper knowledge of (and improved production from) your business processes.

With Digital Models, You Can See Your Company In an Entirely New Light

Digital Twins are truly remarkable. Each Digital Twin is a virtual environment simulating the real world, providing a crucial 10,000-foot aerial view that allows decision-makers to see the impacts of their decisions before putting them into practice. By using Digital Twin technology, business owners and C-suite executives are able to see their business processes in real time, predict the likely outcome of adjustments and changes, and make overall improvements in efficiency that have a positive effect on the bottom line. It’s all thanks to the power of software-based simulations using real-time data in a safe “sandbox” of a digital environment.

But what does a Digital Twin actually look like?

When built using one of the industry’s leading Digital Twin platforms such as Simio or AnyLogic (two of the software packages MOSIMTEC typically works with), Digital Twins look almost like a video game. The virtual representation can be in either 2-D or 3-D, and the company’s processes are accurately replicated on the computer screen using life-like depictions to emulate each process – and to determine how altering variables in one process affects the others.

Results are easy-to-see, easy-to-understand predictive analytical models that look and feel like a real-world digital transformation showing how your business gets business done. For example, a digital simulation of an airport shows planes landing, deplaning, loading passengers or freight, and taking off; a virtual model for a mining company depicts conveyor belts of excavated material leaving the mine for processing; a Digital Twin of a pharmaceutical producer simulates the entire product lifecycle of pharmaceuticals, showing a digital representation of both production and distribution.

Because of their ability to accurately depict real-world processes, Digital Twins make it easy to see how your production currently works – and how your company could produce more efficiently.

Predict Outcomes, Decide Actions, Improve Processes: That’s How To Future-Proof Your Business

One of the strengths of MOSIMTEC is our ability to identify which changes to your business would result in the most transformative outcomes. In business, constant change is inevitable, but constant improvement isn’t. Digital Twins by MOSIMTEC offer the MOST insight and the MOST information to decision-makers, so that together we determine which actions would lead to the MOST improvement.

For every Digital Twin project we undertake, our goal is straightforward: Future-proof your business. That means we use a powerful active simulation of your business to provide you with the MOST knowledge possible, so that you have the information needed to make the best possible decisions about future actions. The predictive maintenance offered by MOSIMTEC Digital Twins allows you to prepare for future changes while making your current systems as efficient as they can be.

Future-proof your business and gain an edge on your competition. Find out how to reduce risk, eliminate bottlenecks, optimize resource utilization, and enhance your bottom line. Work with MOSIMTEC on custom Digital Twins and devise simulation scenarios that offer unparalleled insight into your entire environment.

CONSULT WITH MOSIMTEC FOR DIGITAL TWIN SIMULATION:

Resource Optimization and Risk Management for a Wide Variety of Industries

Before commencing on a Digital Twin journey, one of the pain-points afflicting many MOSIMTEC clients is simply lack of knowledge. They don’t know whether their production processes are operating at optimal efficiency – and there’s no way of knowing without running the simulation to see where the inefficiencies are.

MOSIMTEC’s clients represent a broad array of industries. To list a few:

- Airport and Railyard Operations

- Hospital and Clinic Healthcare Administration

- Pharmaceuticals and Medicine Production

- Logistics and Supply Chain

- Mining and Manufacturing

- Oil and Gas Exploration and Production

- Fast-Food and Quick-Service Restaurants

- E-Commerce and Big-Box Retail

- Aerospace and National Defense

For all the industries listed above and many more, Digital Twins by MOSIMTEC allow clients to gain the MOST insight into how their business runs, so they can run it even better.

Real-Time Digital Twin Simulations That Really Work

If you’re not already familiar with computer-generated virtual environments, a little skepticism about Digital Twins is understandable. How accurately can Digital Twins actually emulate a company’s production system? Twins aren’t always exactly identical, after all.

Our answer won’t surprise you: Digital Twins are the most accurate method available for simulating business processes – if and only if all the different aspects (including all production processes and all real assets) are accurately simulated in the model.

We’ve seen Digital Twins produce uncanny levels of insight for a range of companies, from small businesses to Fortune 500 conglomerates. Of course, the quality of the Digital Twin is only as good as the performance data inputted into it – but the value of the resulting insights and predictive maintenance makes a custom-built Digital Twin a smart investment for any company.

Over many years as a top Business Simulation and Modeling company, MOSIMTEC has helped hundreds of clients create customized Digital Twins to predict outcomes, decide actions, improve operations, and future-proof their business with it’s digital twin modeling services.

Our success is driven by our passion. The professional data scientists and industrial engineers of MOSIMTEC are genuinely passionate about solving problems – and the more complex the problem, the more we like to solve it.

We’ve tackled issues that affect the bottom lines of major corporations, including big box stores, fast-food restaurants, healthcare providers, and mining and manufacturing operations – and we’ve helped those clients come up with innovative solutions thanks to insights gained by using Digital Twins. Put our vast experience, unrivaled expertise, and unbridled passion for problem-solving to good use: Hire MOSIMTEC to harness the power of Digital Twin technology for your company’s benefit.

Want to build your own Digital Twins? Receive hands-on training from MOSIMTEC’s experienced team of expert instructors. Learn basic and advanced concepts for Digital Twin data collection, programming, simulation, and analysis from the Digital Twin industry’s leaders.

MOSIMTEC offers both standardized and customized training courses geared toward every level of knowledge, from introductory user to veteran modeler. Whether your company is new to business simulation or you’ve run simulations in the past, the value you’ll get from MOSIMTEC’s training courses will help your in-house team of technologists develop a deeper understanding of the predictive analytics made possible by Digital Twins.

It takes a fair bit of knowledge – not to mention cutting-edge computing technology – to create Digital Twins that provide meaningful insight into a company’s production processes. Depending on the choice of software platform and the goal of the simulation, a Digital Twin could necessitate usage of real-time data, artificial intelligence, and machine learning to convert real-world processes into virtual reality.

MOSIMTEC is here to help with every aspect of Digital Twin design and programming. From collecting real-world data, to understanding the role of the Internet of Things, to implementing asset twins, our experts guide clients every step of the way toward the goal of greater efficiency.

Rely on our designer’s ability to devise different scenarios that encompass the entire range of your company’s production. Work with MOSIMTEC on Digital Twin Business Simulation and gain insight you couldn’t achieve any other way.

We’re your guide to computer-aided design (CAD)-based simulations – but you’re in charge. We offer clients well-reasoned recommendations for which Digital Twin software platform to use, noting key differences in how each option would work for the same system. The choice of which software platform to go with is at the sole discretion of the client.

Primarily, MOSIMTEC works with two powerful and highly regarded business simulation software applications: Simio and AnyLogic. Both packages contain attractive features which lend themselves to particular projects. To wit: AnyLogic is indicated for accurate simulations of complex interrelated events in a multi-method modeling environment; Simio works well for companies just beginning their simulation journey, with drag-and-drop design elements and high-quality animated output.

Depend on the advice of MOSIMTEC’s data scientists for deciding upon the right Digital Twin software platform, but have the confidence of knowing that the choice is entirely yours.

Our clients say

Success here will be exported throughout the world, changing perceptions, pioneering and opening new markets and saving lives. -DroneAmerica.com

MIKE RICHARDS

Simulation starts where Statistics ends…

BIG FOUR CONSULTING FIRM

Very hands on. You were very interactive and supportive of any questions that popped up during the course.

Pharmaceutical Automation Solutions Provider

The course provided a great overview of all the software as well as a good base to begin building models and refining our skills through repetition. It was exactly what I was looking for.

Deere & Company (John Deere)

We had a good time and learned a lot… Thanks for all your help.

National Institutes of Health (NIH)

Thank you guys for the extraordinary job! Very impressive.

Mining Corporation

Need to know what you are going to do, before you do what you are going to do.

Class I Rail Carrier

Commercial drones will change the way we do our jobs, improve our decision-making and save lives.

Jonathan Downey

Especially taking the variability into account… that’s phenomenal what you guys are doing.

Class I Rail Carrier

It’s the most advanced we’ve seen any customer.