Design. Test. Optimize. Before you Build.

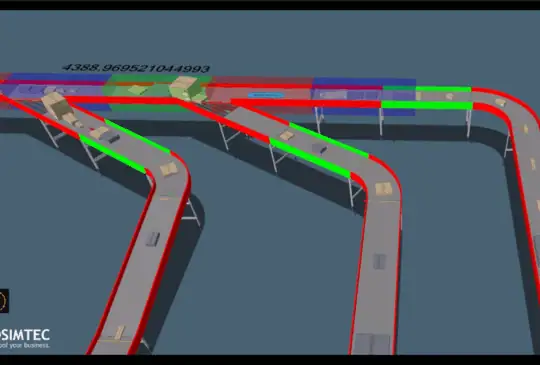

Using Emulate3D by Rockwell Automation, MOSIMTEC creates accurate digital twins of your automation systems, so you can validate control logic, simulate real-world performance, and reduce costly downtime – before deploying a single piece of hardware.

The AutoMod Replacement.

AutoMod by Applied Materials had been the market leader for simulation of material handling systems. Emulate3D is the top choice for companies looking to replace their AutoMod simulations. Emulate3D includes a library of hundreds pre-built industrial equipment, ability to write your own code/logic in C# and a physics engine to simulate various forces.

MOSIMTEC: Your Emulate3D Consultants.

MOSIMTEC team has decades of experience modeling material handling systems that include:

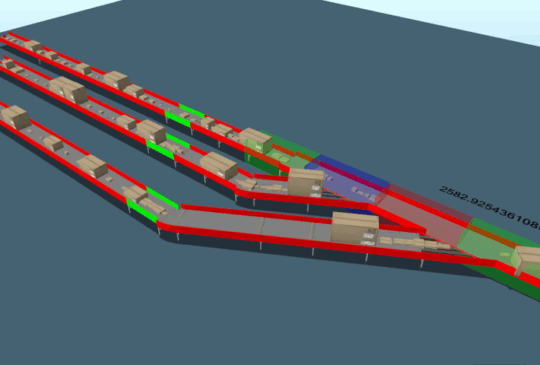

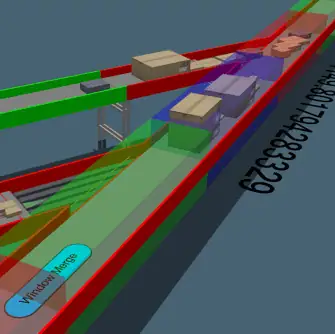

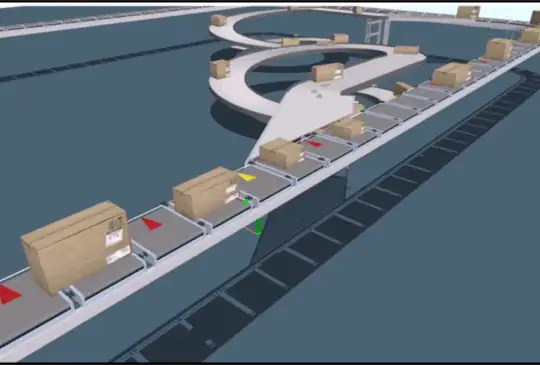

- Conveyor networks

- Sorting & Merging systems

- Goods-to-Person (GTP) workstations

- Pick-to-Light (PTL)

- Breakpack systems

- Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR)

- Automated Storage & Retrieval Systems (ASRS)

- Trailer and Dock management.

Emulate3D simulation software

- Optimize System Throughput

- Experiment with layout changes, bottlenecks, and performance improvements in a risk-free environment.

- Visualize System Behavior

- Create interactive, animated 3D models that help you and your stakeholders understand system performance in real-time.

- Reduce Commissioning Time

- Test and validate PLC code virtually – cutting on-site debugging time dramatically.

- Bridge Operations Technology (OT) and Information Technology (IT)

- Integrate seamlessly with your control systems and enterprise data to make better decisions, faster.

Emulate3D Simulation Software

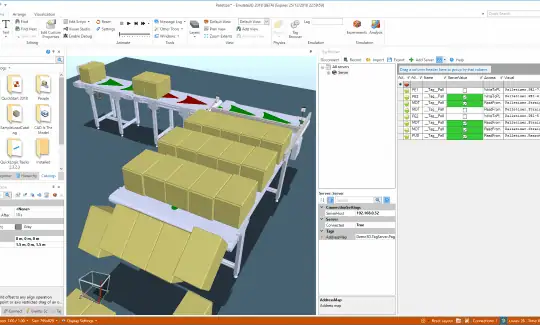

Emulate3D allows you to connect directly to real PLCs or virtual controllers, letting you test and debug actual control logic in a safe, simulated environment—before any physical systems are built. You can import CAD files (SolidWorks, Inventor, STEP, etc.) and turn them into functioning simulation models automatically, reducing rework and speeding up deployment.

Emulate3D software can be used to

- design Automated Warehouses and Distribution Centers (DC),

- model Conveyor and Material Handling Systems,

- design Manufacturing Line Simulation,

- understand challenges in Robotics Integration and

- optimize Packaging Systems.

Emulate3D supports:

- Emulation mode (real PLCs)

- Simulation mode (internal logic)

- Demonstration mode (animated demos for sales/training)

You can import CAD files (SolidWorks, Inventor, STEP, etc.) and **turn them into functioning simulation models automatically**, reducing rework and speeding up deployment.

It doesn’t just simulate; it creates interactive, animated 3D models that act as live digital twins, showing exactly how your system behaves under real-world conditions.

Emulate3D includes multiple physics engines that offer three distinct physics modes to support simulations to test various scenarios:

- Volumetric: useful for simulating stacking loads, positioning objects on conveyors, effect of friction, & interaction with sensors.

- Planar: Simpler and less CPU-intensive than Volumetric while providing highly accurate representation of parallel loads on conveyors, photo-eye interactions and accelerations.

- Linear: Fastest physics engine that abstracts away CPU-intensive computation for larger projects while preserving interaction of loads with material handling systems.

Our clients say

Success here will be exported throughout the world, changing perceptions, pioneering and opening new markets and saving lives. -DroneAmerica.com

MIKE RICHARDS

Simulation starts where Statistics ends…

BIG FOUR CONSULTING FIRM

Very hands on. You were very interactive and supportive of any questions that popped up during the course.

Pharmaceutical Automation Solutions Provider

The course provided a great overview of all the software as well as a good base to begin building models and refining our skills through repetition. It was exactly what I was looking for.

Deere & Company (John Deere)

We had a good time and learned a lot… Thanks for all your help.

National Institutes of Health (NIH)

Thank you guys for the extraordinary job! Very impressive.

Mining Corporation

Need to know what you are going to do, before you do what you are going to do.

Class I Rail Carrier

Commercial drones will change the way we do our jobs, improve our decision-making and save lives.

Jonathan Downey

Especially taking the variability into account… that’s phenomenal what you guys are doing.

Class I Rail Carrier

It’s the most advanced we’ve seen any customer.