Bottlenecks can be the bane of a project manager’s existence, especially if their mandate is removing obstacles and improving manufacturing efficiency.

Bottlenecks are the processes in your system that limit its entire capacity, delaying subsequent processes, and often causing a domino effect on downstream productivity.

There are a countless number of issues that can be bottlenecking your process, and it can be difficult to know where to even begin.

So how do you find these manufacturing bottlenecks?

In this blog, we’ll explore the different types of bottlenecks your manufacturing operations may encounter and provide tips for solving them.

How Manufacturing Bottlenecks Are Different

Manufacturing bottlenecks can be split into the following categories:

- Production Line Bottlenecks

- Supply Chain Bottlenecks

- Employee Bottlenecks

Each one of these bottleneck types can drastically reduce throughput, cause delays, agitate your customers, and affect employee morale.

Short-Term vs Long-Term Manufacturing Bottlenecks

When examining bottlenecks, it is important to differentiate between the short-term and long-term.

Short-term manufacturing bottlenecks are usually temporary and unavoidable. In a factory, this could be a key technician falling sick or going on vacation or a machine requiring maintenance.

Spending time trying to eliminate short-term bottlenecks is futile. They are unpredictable, and their impact can vary from negligible to enormous delays if hit at the most unfortunate time.

On the bright side, you can usually account for short-term bottlenecks. If someone is going on vacation, you can plan for that time off, and by holding a regular maintenance schedule, you can reduce the number of inopportune machine breakdowns.

Your focus should instead be on long-term manufacturing bottlenecks. These are systemic bottlenecks that are causing persistent production delays. Thus, you focus should be on removing them.

Many small-to-medium enterprise (SME) manufacturers have to deal with long-term bottlenecks. Examples can be situations like a machine with a consistently long queue or high downtime on the factory floor due to long lead items.

Long-term manufacturing bottlenecks are the bottlenecks that you can work towards eliminating.

5 Killer Ways to Improve Manufacturing Efficiency

Identifying and Solving Manufacturing Bottlenecks

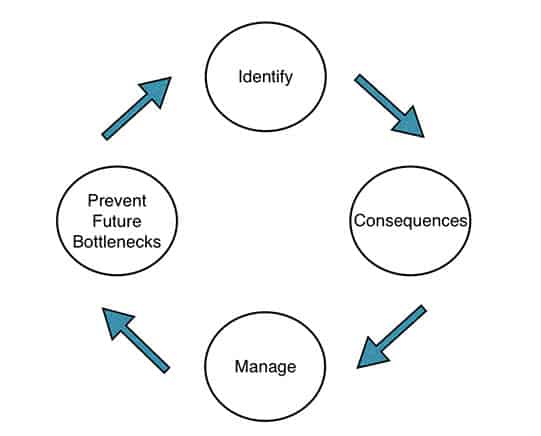

Bottlenecks in manufacturing must be tackled with a four-pronged approach:

- Identify what areas have become bottlenecks by evaluating metrics such as throughput, capacity, and wait time.

- Evaluate the consequences of those bottlenecks. What operations are being delayed as a result?

- Manage those bottlenecks. What can you do immediately to solve them?

- Work towards preventing future bottlenecks from arising.

Production Line Bottlenecks

Build Up of Accumulation

Production line processes that accumulate longer queues (also known as a bottling line) are often a result of input coming in faster than the process can handle.

In most cases, the process that is accumulating the longest queue is the bottleneck.

How to Fix It

If you have deep insight into every individual process, you’ll be to find the processes that are creating these bottlenecks. The solution may be simple; it could be that an operator requires more training or a machine is breaking down frequently.

Limited Throughput

Throughput is linked to the output of any piece on a production line. Look at what your expected throughput is; if you find that it is being limited, you can be certain that there are serious bottlenecks you must identify.

How to Fix It

Change the throughput of different machines one at a time. You’ll find that in most cases, not every machine is operating identically. The machine that affects the overall output of your factory is the bottleneck and can be adjusted accordingly.

Machines at Full Capacity

Your factory keeps track of each production line’s ‘percentage utilization’. Often, the bottlenecks in each production line are those that are operating at near full capacity. That can lead to other processes following the bottleneck to operate at lower capacity.

How to Fix It

Increase the capacity of any bottlenecked machine, therefore increasing the capacity of the entire production line.

Increase in Wait Times

Similar to full capacity, wait time bottlenecks are easy to discover by tracking the downtime of machines. In most cases, the bottleneck is the machine that comes before the machine with the highest wait times.

How to Fix It

Once you’ve identified the machine that is causing any holdup, you can work towards eliminating that bottleneck. It can be as simple as increasing or decreasing capacity or a bit more difficult if you find that constant breakdowns are the problem.

Simulate Your Production Lines to Discover Bottlenecks You Never Would Have Caught Before

Supply Chain Bottlenecks

Material Constraints

Your entire production is reliant on your firm’s resources. Material bottlenecks can appear due to:

- Poor management of inventory that creates situations where factories may be waiting on supplies.

- Inadequate forecasts of production that create unexpected problems.

- Incomplete financing

- Changing the mix of products

Any number of factors can contribute to a poor flow of materials through your supply chain.

How to Fix It

While it may be impossible to eliminate unexpected disruptions, creating and sticking to a comprehensive supply chain plan that accounts for some variation can prevent extreme bottlenecks from arising.

Equipment Constraints

Equipment bottlenecks can simultaneously be the simplest and most complicated bottlenecks to fix. On one hand, you’ll be immediately aware of any equipment breakdowns.

But on the other hand, manufacturing machinery is highly specialized and replacing or repairing those machines can cause enormous bottlenecks.

It is not uncommon for highly specialized equipment to have long, sometimes year-long waiting periods, requiring you to substitute broken equipment with less productive machines.

How to Fix It

Critical equipment can be damaged at a moment’s notice. Other than regular maintenance schedules to keep this equipment operational, you must have contingency plans in case of a worst-case situation.

You do not want to be caught off-guard by any critical machinery breakdowns.

Transportation Constraints

The challenge with transportation constraints is determining what is just a short-term bottleneck and, on the other hand, identifying long-term bottleneck issues.

For instance, late shipments due to weather can cause delays, but solving the ‘weather bottleneck’ is out of our scope.

However, transportation bottlenecks that you can solve are consistent delays from the same source.

How to Fix It

Similar to the rest of your supply chain, you must collect detailed data on every stage of the supply chain. If you find consistent delays from a single location compared to any others, you can learn what that location is doing that others aren’t to find the bottleneck.

Read more about manufacturing efficiency:

- 4 Big Disadvantages of Lean Manufacturing — A Criticism of Six Sigma’s Approach

- 5 Killer Ways to Improve Manufacturing Efficiency

- 12 Disastrous Operational Issues That Will Cost Your Business Millions

(Source: University of North Texas)

(Source: University of North Texas)

People Bottlenecks

Employee Processes

Employee bottlenecks can come in many forms:

- Poor training that leads to inefficient work

- Low morale

- An ineffective flow of communication

- Lack of standards, creating situations where different employees are doing the same work with varying degrees of success

Unforeseen bottlenecks, such as an employee quitting, can turn into long-term bottlenecks if it is an employee with highly specialized skills that you cannot replace.

How to Fix It

How you go about solving employee bottlenecks depends on which of the above plagues your firm. To start, we suggest identifying your human assets and creating comprehensive training programs to ensure maximum production.

Additionally, in the case of single employees with highly specialized skills that are irreplaceable, you must create training programs where they are able to transfer their skills.

Management Efficiency

Did you know that in a recent Career Builder study, just 42% of managers stated that they received management training?

Just like employee bottlenecks, managerial bottlenecks can arise from inexperienced managers operating inefficiently.

This can be anything from overworked managers not having enough time to make any approvals, causing delays to different managers operating with different standards, creating workplace confusion.

How to Fix It

To start, create a standard that all managers must stick to. This will eliminate any confusion and empower employees, rather than hinder them. Additionally, if any managers are causing delays due to workloads, see what can be taken off their plate.

And remember, good management starts from the top. Lead by example!