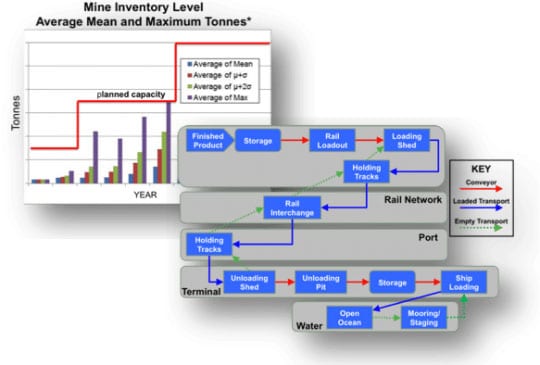

Mining Operations are a Complex collection of inter-related Processes

Mining systems have hundreds of interdependent factors, each with significant level of variablity. Bottlenecks are hard to identify as they continously shift throughout the life-of-mine (LOM). Mining simulation and Digital Twins are unique in their ability this complexity and variability to make rapid decisions.

Drill Down Into Mine Operations By Using Advanced Mining Simulation

Leverage insights generated by our simulation experts to gain a holistic view of your mine. You can reduce waste, ensure a smoother transportation of materials, better manage staff, and improve operations as a whole.

MOSIMTEC’s mining simulation provides actionable insights to:

- Meet production targets

- Better manage labor

- Optimize scheduling of labor & equipment fleet

- Balance maintenance costs vs. long-term asset protection

MOSIMTEC is the North America representative for MineTwin Mining Simulation Software.

MineTwin is a configurable simulation-based decision support tool for open-pit and underground mines.

Comprehensive and Insightful Models

Mosimtec’s mining simulation services have provided comprehensive and insightful models for over a hundred successful modeling projects for our clients located throughout the globe. By using industry-leading advanced simulation software, we can enable you to succeed with powerful insights designed to improve your mining operation. Contact us to learn how our mining simulation software will improve your mine.

Why Mining Simulation Will Improve Your Operation

Every large mining operation has dozens of different moving pieces that, if the venture is to be successful, must be properly managed and improved upon. There are so many moving parts, however, that getting them to work efficiently together can become a challenge. That’s where MOSIMTEC’s mining simulation models and mining consulting services come into play. We deliver powerful tools backed by comprehensive expertise that will help you.

With our powerful mining simulation tools, you can get a complete view of each area of the mine and anticipate where delays may occur along the supply chain. As a result, you can adjust resources to mitigate against this, and ensure that you are making shipments on time.

Whether it is time, resources, or products, there is always something wasted in any operation. Mining is no exception to this. With so many staff, processes, machines, and other moving pieces, waste reductions can be made by using insights generated by MOSIMTEC’s mining simulation software and consulting.

Once ore has been extracted by the mining operation, it needs to be transported to a stockpile, a processing plant, or a customer. However, this is not a straightforward process. How many trucks, trains, conveyors, or ships will will be needed? Where are the bottlenecks and constraints that prevent the supply chain from moving smoothly? Simulation is the perfect tool to answer these difficult, yet critical question.

Mining operations employ a variety of staff and labor, including electricians, mechanics, engineers, and many more. Each of these are needed to keep your mining operation running smoothly. Keeping all staff members organized, however, in such a way that the mine is as productive as possible is an extremely challenging task. Mining simulation software and consultation can provide guidance on how to best organize your people.

You can gain a holistic view of how your staff interact with machinery and the mine in general. Additionally, you can estimate the impact of no-shows, labor productivity levels, or a contracted workforce on the bottom line.

Mine operators struggle to balance preventive maintenance against unplanned downtime. Simulation models can assess the effects of changes in availability, as a result of changes in maintenance strategies – e.g. opportunistic maintenance vs planned maintenance. Also, simulation modelling can determine the best time to replace assets given maintenance costs, failures and repair frequencies, and utilization.

Processing ore is an expensive and complicated operation. Thus, understanding the effect of process changes on the overall cash performance of the business as opposed to local (sub) optimization is of primary importance.

Some questions that help in assessing these changes are: What future constraints might hurt recovery and throughput? If plant reliability can be altered (improved), will there be an improvement in tonnage and recovery? Is this potential improvement substantial enough to warrant the cost of investment?