A medical device manufacturer needed to understand the throughput impacts of a proposed instrument change. The company also needed to understand if and how scheduling algorithms should change given the proposed physical change to the device.

- Device complexity and high variability in health care systems made simulation modeling a perfect fit to understand the impact of changes to the system.

- The simulation environment was utilized to understand why current algorithms may be sub-optimal and test changes to the sequencing of work in the system.

- The model was delivered with flexible input parameters, so the device manufacturer could continue to experiment with future proposed changes.

Key outcome were:

- The medical device manufacturer found throughput increases met and exceeded the minimum required to move forward with the design modification.

- A suggested change to the scheduling algorithm, resulting from the simulation engagement, increased instrument throughput by an additional 5%.

Other Case Studies

- All

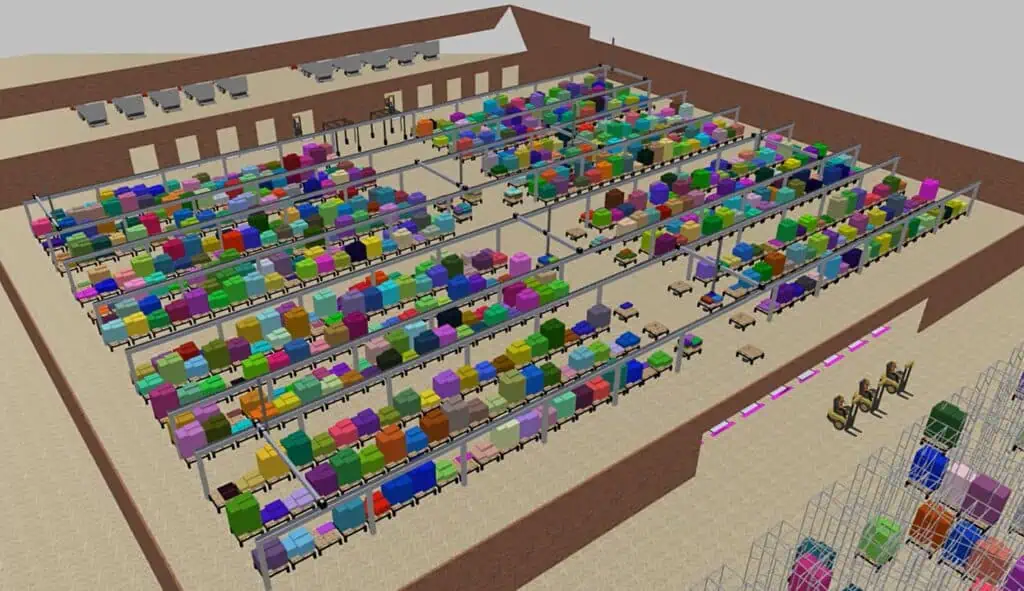

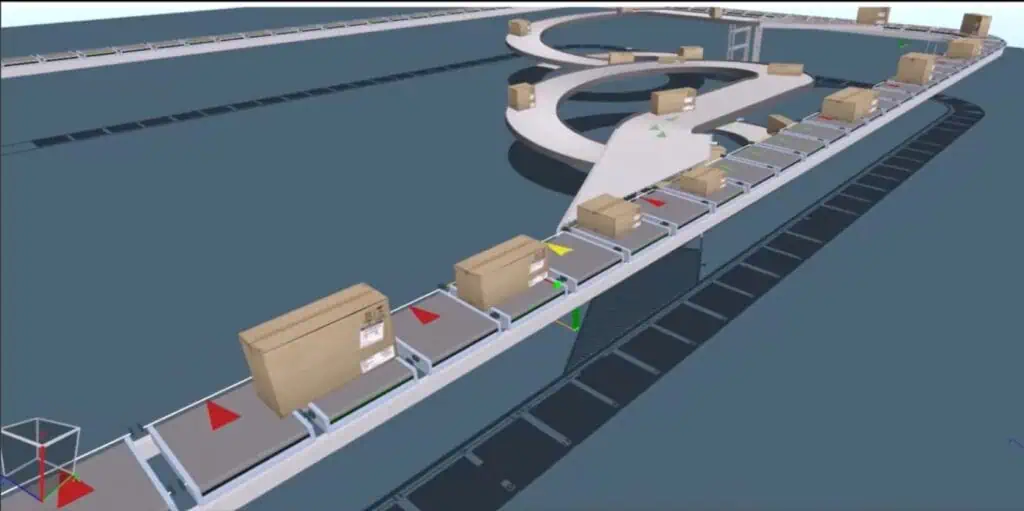

- 3D simulation

- AMR

- Anylogic

- automated mobile robots

- bottlenecks

- conveyor design and implementation

- conveyor physics engine

- Distribution Center

- Emulate3D

- Emulate3D 2024 User Group Meeting

- industrial automation

- Logistics

- material movement analysis and design

- Oil-and-Gas

- order fulfillment

- Rockwell Automation

- Simulation

- slugging options

- terminal simulation

- throughput validation