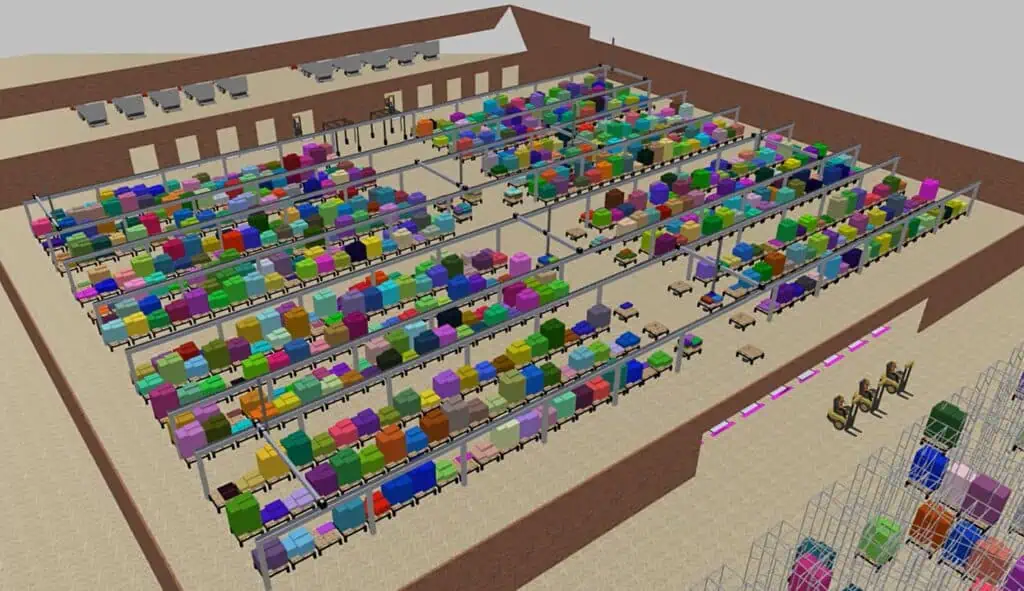

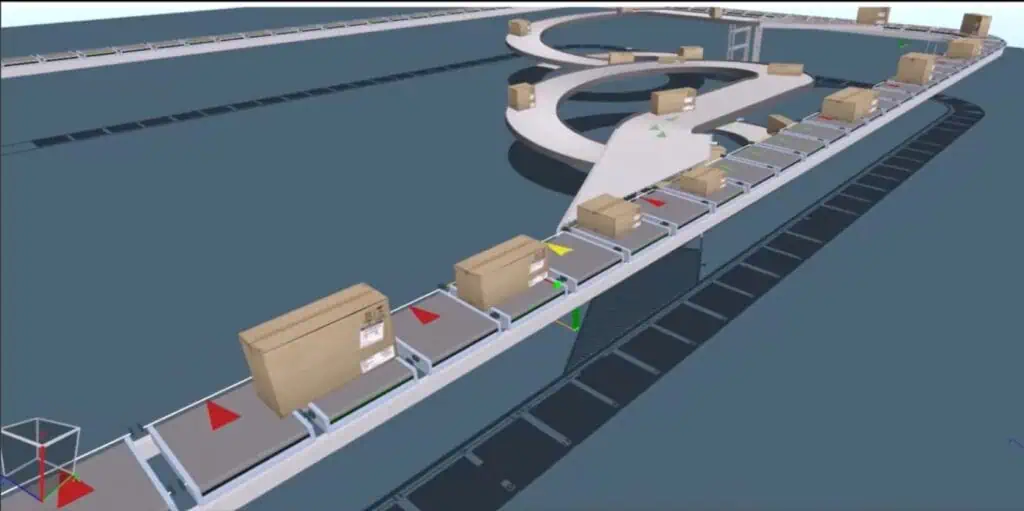

Customer is designing and developing improvements at an existing facility to increase their terminal and trans-loading business. Use modeling and simulation technology to represent the system in a dynamic environment, therein incorporating inherent variability, to validate the design and make informed decisions.

Overall project benefits include:

- Provide throughput related design input for engineering with regards to the infrastructure being designed and installed.

- Provide experimental feedback for developing the operational logic for efficient business operations.

- Serve as basis for optimization studies for increasing the profitability and quality of services provided to customers.

Early quantifiable benefits realized through model based input*:

- Minimum $70K saving in Phase 1 by optimal resource scheduling

- $350K / year saving by avoiding three 2-hour delays per month.

- Additional 2 trains per week site capacity.

* Actual project result modified to protect client confidential information

Other Case Studies

- All

- 3D simulation

- AMR

- Anylogic

- automated mobile robots

- bottlenecks

- conveyor design and implementation

- conveyor physics engine

- Distribution Center

- Emulate3D

- Emulate3D 2024 User Group Meeting

- industrial automation

- Logistics

- material movement analysis and design

- Oil-and-Gas

- order fulfillment

- Rockwell Automation

- Simulation

- slugging options

- terminal simulation

- throughput validation