In farming and sugar cane production, getting raw materials from the fields to the factory on time is crucial. Today, thanks to simulation tools like AnyLogic, analysts can test hypotheses digitally before companies spend their budget on solutions that might be impractical.

This case study is about MOSIMTEC and Crouch Engineering succeeding in the U.S. Sugar project. We’ll go step-by-step from the sugar refinery model in AnyLogic Cloud to a string of experiments in a railway design tool built on top of the model and finally get to a solution no one had thought of.

About the end-client and consultants

U.S. Sugar is the largest sugar cane producer in the United States. The company owns the entire supply chain for this niche market. Their farm is almost a quarter million acres in South Florida. They farm sugar cane, harvest, transport, and refine it.

MOSIMTEC is a simulation consulting firm with over 13 years of experience. They are especially good at railway simulation. They work with Crouch Engineering, who have been in the railroad business for 32 years, on projects involving manufacturing transportation, railway optimization, and rail yard management.

Problem

The U.S. Sugar refinery complex is a system of two delivery points and a sugar mill. Sugar cane is dumped into hoppers to feed the mill. Maintaining a constant feed is crucial, as any shutdown leads to significant restart costs and potential operational consequences. When the sugar cane is in season, the process runs 24/7. There are always trains staged and ready to go to keep the refinery fed.

Sugar mill rail delivery points

For sugar cane transported from the field to the refinery in cane cars, a specialized type of railcar with specific sizes and features is needed. The fleet comprises around 800 cane cars.

The main problem is the age of cane cars; most of them are 60-70 years old. This leads to a high maintenance cost, but replacing the entire fleet of cars also exceeds the U.S. Sugar budget; it would cost $80 million. However, even if they would have agreed to spend the money on a new fleet of cars, the sugar mill is specifically sized for these old cane cars.

So, U.S. Sugar delegated the search for a solution to MOSIMTEC and Crouch Engineering. They had to find a way to transport sugar cane from fields to the refinery on time and ensure that the changes would result in a well-running system that doesn’t cost a fortune.

Solution

Initially, the MOSIMTEC and Crouch Engineering teams proposed the idea of a transfer hub with proper rail yard management. It implied building a transfer system to utilize coal cars for transporting the product from the field to the refinery.

Transportation steps:

- Cane from the field comes in coal cars.

- On the rail yard it is moved from coal cars into cane cars.

- Cane cars go to the refinery.

- The materials are loaded into the sugar mill.

While adding a transfer system contradicts lean principles in industrial engineering, the limited options and time deadline made the extra transfer point a surprisingly attractive solution. MOSIMTEC used the AnyLogic Rail Library to quickly go through the modeling stage.

Sugar cane refinery model

Sugar cane transportation coordination at the U. S. Sugar facility

The railway model built in AnyLogic simulation software used a Google Map satellite image of the sugar cane refinery. The green and blue lines at the top are cane cars continuously feeding into the sugar mill. The dynamic blue bars depict hoppers; if those ever reach zero, the refinery would shut down. The same process we’ve described in our AnyLogic 9 workshop. The multicolor system shows coal cars that are coming in from the field. The yellow lines are the empty cane cars that are to be filled up.

The sugar cane refinery model was the base for a railway design tool that would be used to run experiments and test ideas, for example, to implement rail yard management with a transfer system.

Experiments with rail yard management and an additional track

The main advantage of the proposed transfer station is its buffer. It decreased the pressure on cane cars by shortening the transportation distance. As a result, there is no need for cane cars and coal cars to be at the transfer station at the same moment. So, proper rail yard management resulted in two autonomous systems that support each other’s workflow.

However, at this stage of the project, one big point of concern was one of the tracks. After the cane cars emptied, they would need to use that track to return to the staging area. Meanwhile, the coal cars had to reverse over that track, then switch to exit, making it a bottleneck for all trains.

To address the rail traffic block issue, the alternative was to construct an additional track, indicated by the red line in the model. The consultants expected it to enhance capacity and prevent trains from sharing the same track simultaneously.

Extra track experiment

Railroad engineers from Crouch Engineering knew that this additional track would provide more capacity, but it cost $3 million. Such money spent on adding a rail track conflicted with U.S. Sugar’s budget. To see how this solution would affect the railway optimization, MOSIMTEC added the extra track to the model and ran the experiment in the railway design tool.

Experiment input

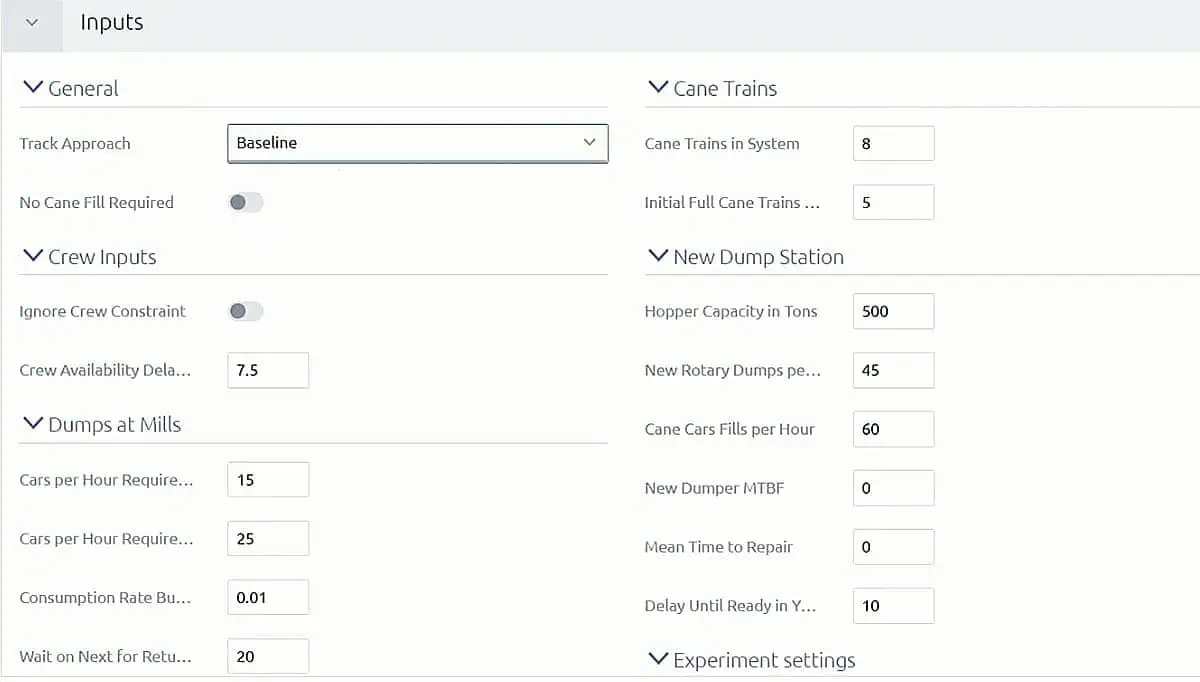

Data input in the railway design tool

Data input in the railway design tool

Under time limits, MOSIMTEC uploaded their model into AnyLogic Cloud and used it to create a simple railway design tool. They set the parameters and ran several experiments to see if such a costly solution might result in significant benefits while mitigating negative side effects.

Key input information included:

- configuration and design of the track

- hopper capacity

- number of cane cars per hour

- available cane trains

- target processing rates

- crew policies

Experiment run

Experiment run in the railway design tool with an additional run-around track

One of the highlights of the experiments run in the railway design tool was the animation. With AnyLogic Cloud, you can support your numbers with statistics and 2D or 3D animation of the simulation. The advantage, which was proven effective in the U.S. Sugar case, stemmed from the appropriate use of animation. This aided C-level managers in visualizing the results of experiments and delving into detailed workflow intricacies.

Experiment output

Experiment output in the railway design tool

All the experiments that were run in the railway design tool created by MOSIMTEC in AnyLogic Cloud were also supported by a wealth of statistics. In the U.S. Sugar project, the core metric was refinery starvation. So, if MOSIMTEC detected any combination of inputs leading to a mill shutdown, they rejected the scenario.

After multiple experiments, the idea of an extra track was dismissed. Although it didn’t make the sugar mill stop, it showed no economic benefit for the company.

Results

After running multiple experiments and testing different hypotheses, MOSIMTEC and Crouch Engineering found a solution that worked well in simulation and met U.S. Sugar expectations. The solution turned out to be an additional rotary dumper. The idea, tested without great expectations, improved downtime, and maintenance, leading to the anticipated track performance.

The case highlights a common outcome in simulation modeling. Questioning one idea can yield unexpected results. Without experiments in the railway design tool and simulation model, this critical insight might have been overlooked.

Based on these findings, U.S. Sugar managers opted to review their budgeting and explore a third type of car alternative that would still integrate with the refinery. The choice to test scenarios with a simulation model helped them avoid costly decisions.

As long as U. S. Sugar has access to the railway design tool, they can run experiments even after the work with MOSIMTEC is finished. When they need output data to review the decision-making process, they can find it in a couple of clicks.

The case study was presented by Amy Brown Greer from MOSIMTEC at the AnyLogic Conference 2023.

photo credit: https://winknews.com/2018/07/18/campaign-finger-pointing-whos-taking-money-from-sugar-industry/