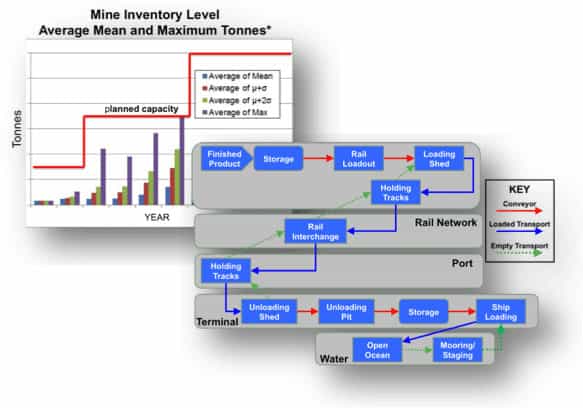

Evaluate the supply chain to test performance under a range of different situations, events, and constraints. Also focus on key areas including cost, capacity, equipment, inventory, transit time, and other areas, along with risks, bottlenecks, and their potential impacts.

- A complete model of the supply chain was developed, including detailed data analysis.

- The first 10 years of system ramp-up, through steady state, was represented and different scenarios configured for this period.

- Results of the project identified >$10million in savings by reducing CapEx investment (storage and train sets).

- Also determined the best timeframe to construct and deploy assets over 10 year period.

Other Case Studies

- All

- AMR

- Anylogic

- Dairy Farm Simulation

- Digital Decision Support

- Digital twin disease modeling

- Distribution Center

- Equipment Fleet Sizing

- Food system resilience and pandemics

- High Pathogenic Avian Influenza (HPAI)

- HPAI risk model

- Influenza virus mutation risk

- Medium-Term Mine Planning

- Mine Haulage Systems

- MineTwin

- MineTwin Case Study

- Mining Bottleneck Analysis

- Operational Excellence

- Picking

- Predictive disease modeling

- Production Ramp-Up

- Shaft Capacity Analysis

- Simulation

- Simulation-Based Planning

- Slotting

- underground mining

- Zoonotic disease risk modeling