The challenges faced by the mining industry are only getting more complicated, but the call for reducing operational costs and increasing profitability are a constant regardless of the external factors (e.g. regulatory factors and market volatility). Thus, decision-makers like yourself must have strong insights about your mining operations, such as the system bottlenecks preventing operations from sustaining a profitable pace of production.

Profitability – i.e. sustaining or increasing revenue while controlling cost – is the primary issue of concern. Andy Reynolds, General Manager of Energy, Mining and Environment at the National Research Council of Canada (NRC) noted: “If these [mining] companies want to operate and make money, they are going to have to be able to extract metals and minerals at a lower cost.”

However, in order to design and execute a proper cost-control or resource-optimization strategy, you must have strong operational insights into your mine, especially in terms of how your mining operations relate to key external factors.

External Issues Affecting Your Mining Operations Plan

The operational costs of your mining operations are affected by a number of external pressures, including market volatility and regulatory factors. According to KPMG’s 2018 Insights into Mining survey, commodity price was identified as the number-one risk by mining industry executives.

The Top 5 Risks Identified by Mining Executives

The prices of commodities (including mineral ores) are determined by macroeconomic factors, but they directly impact your revenue (by setting the price of your ore). If those prices decline, you will need to know what you can do to your mine to sustainably throttle operations.

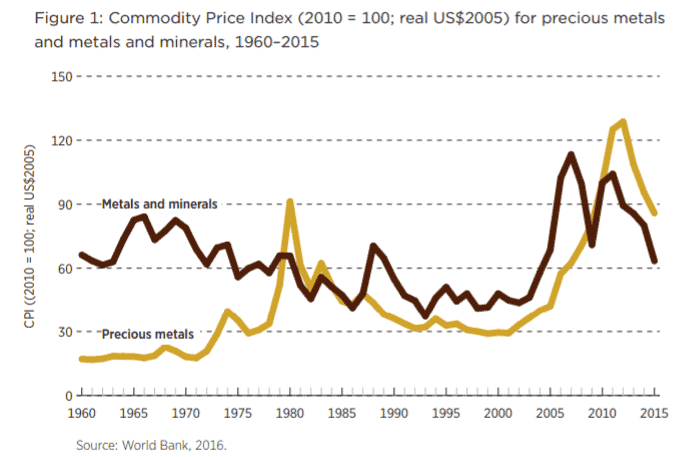

Commodity Price Index (2010=100; real US$2005)

for Precious Metals, Metals and Minerals

Commodity prices had peaked in 2010-2012, but dropped sharply in subsequent years, causing a sharp decline in revenue for mining operations all over the world. The decline has also caused – and left – investor and financing hesitance in expanding mining operations.

Commodity prices had peaked in 2010-2012, but dropped sharply in subsequent years, causing a sharp decline in revenue for mining operations all over the world. The decline has also caused – and left – investor and financing hesitance in expanding mining operations.

The second-highest area of risk – i.e. the risk of delay in gaining mining exploration permits – is a regulatory factor that affects discovering and mining new ore deposits, i.e. your opportunities for expanding your revenue base, especially for the long-term.

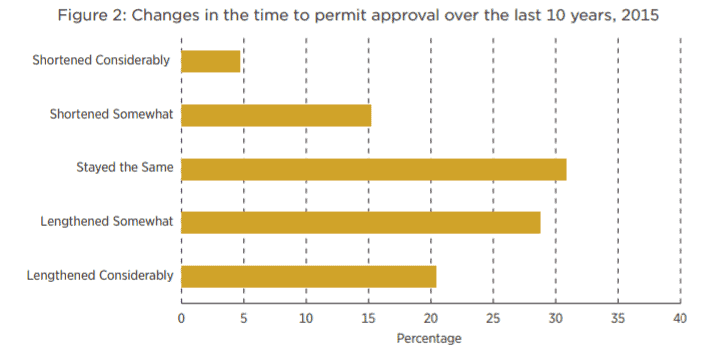

Changes in the Time to Permit Approval

Between 2005 and 2015

According to a survey of 2,700 global mining executives and managers by the Fraser Institute, 50% of respondents “indicated that the time for permit approval has increased from ten years ago and 20% indicated that the time has lengthened considerably.”

Successfully navigating through these risks requires possessing strong insights of your mining operations. These insights will help you identify what factors are fuelling your costs, managing your equipment usage and securing stakeholder buy-in.

The Essential Operational Insights of Your Mine

With the aforementioned factors in mind, the following areas are the most important operational insights you must have on your mining operations.

Identify Your Bottlenecks

You must identify the system bottlenecks of your mining operations. These are the inefficiencies in your mining operations – e.g. a specific process, certain equipment or poor mine design – that are preventing the mine from reaching its output potential.

However, it’s important that you not mistake a short-term constraint for a system bottleneck. For example, a broken or out-of-service machinery will certainly delay your output, but it may not be the bottleneck that is responsible for long-term loss of revenue.

Correctly identifying the system-level bottleneck will enable you to begin rectifying it by pushing the constraint to the area requiring the highest amount of investment. Rectifying that constraint would mean improving the most significant subsystem of the mine, thus maximizing returns.

Understand Your “Main Levers to Pull”

As discussed above, your mining operation can be affected by a range of external factors, many that are largely out of you and the mining industry’s control.

From price volatility or friction in the regulatory space (denying mining exploration permits), you need to know how you can promptly adjust your mines’ operations to align with current realities.

For example, in response to a decline in commodity pricing affecting ores, you should have an insight into how you can throttle or reduce ore output from your mines, especially in regards to existing equipment and processes.

Cost Optimization Opportunities

Due to shareholder pressure, limited access to credit, financing for new equipment or external factors (e.g. commodity price volatility), you may be required to optimize your resources.

This requires lowering the availability of certain equipment, especially those wherein reduced availability does not affect your mineral ore recovery output. The idea is to reduce the cost of mining without reducing the results of your mining operations.

MOSIMTEC’s Resource Optimization Consulting

Offers an Average 10X ROI

Understand Current and Future Revenue Sources

Strategically, you must clearly understand your current and future revenue sources. In mining, fundamentally speaking, there are only two revenue sources: (1) your current mining recovery and (2) your future mining opportunities.

In terms of the latter, you must know your prospects of exploration (and building an ore body of knowledge). However, this is directly influenced by the regulatory environment (which can delay or even remove the prospect of exploration) and broader political realities. Likewise, you could also run into financing obstacles for exploration and new mining projects.

Thus in the absence of viable future revenue sources, you must have answers for increasing the profitability of your existing mining operations. In other words, understand how you can optimize your operational costs while maintaining the right output in response to current market realities.

Next Steps

You might be asking, “how do I acquire those strong insights?” Because there are many factors in play, you will require strong cross-functional expertise with deep mining industry experience.

For example, correctly identifying bottlenecks alone would necessitate a team of mining industry experts with knowledge of equipment, supply chain dynamics, human capital and market factors in combination with modeling and simulation tools.

This team will equip you to recognize as well as challenge incorrect assumptions, charter fully defined plans for rectifying problems and, ultimately, provide you the confidence to objectively inform your stakeholders of your current and forthcoming mining plans.

By combining mining industry experience at the Fortune 500-level with strong cross-functional expertise and industry-leading simulation tools and mining optimization software, MOSIMTEC has consistently provided mining companies with successful resource-optimization and revenue-increasing strategies. Contact MOSIMTEC today to discuss how we can provide you with comparable actionable insights.