Provide a visualization tool to serve as a communication medium of planned mining operations and supply chain. Subsequently apply this mining simulator tool to help with engineering design and process improvement.

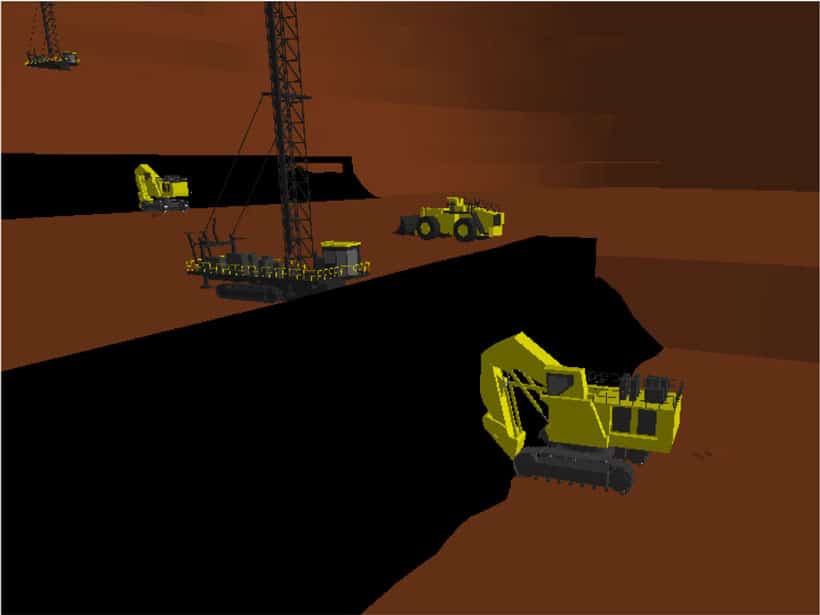

Utilized advanced analytical tool with 3D animation to develop a dynamic model of planned operations.

Model included mine pit, equipment, buildings, plants and transportation system across 5 models covering the entire mining value chain.

Developed invaluable quantitative and qualitative insights:

- Getting enterprise excited about the initiative.

- Communicating to external stakeholders (buy-in)

- Feasibility level validation – “see” the operation in action and inform silos of engineering teams.

- Afford opportunity to look across different options to develop site – impact on logistics, fleet, supply chain.

Benefits lie in the Journey, as well as the Destination.

Other Case Studies

- All

- AMR

- Anylogic

- Dairy Farm Simulation

- Digital Decision Support

- Digital twin disease modeling

- Distribution Center

- Equipment Fleet Sizing

- Food system resilience and pandemics

- High Pathogenic Avian Influenza (HPAI)

- HPAI risk model

- Influenza virus mutation risk

- Medium-Term Mine Planning

- Mine Haulage Systems

- MineTwin

- MineTwin Case Study

- Mining Bottleneck Analysis

- Operational Excellence

- Picking

- Predictive disease modeling

- Production Ramp-Up

- Shaft Capacity Analysis

- Simulation

- Simulation-Based Planning

- Slotting

- underground mining

- Zoonotic disease risk modeling