Simulating an Automated Breakpack System in a Walmart Distribution Center

This case study focuses on the simulation of a soon-to-be implemented automation system within a Walmart Canada distribution center. The above video was presented at the WinterSim conference.

Background

As of July 31, 2020, Walmart Canada has 408 stores, including 343 supercenters, in almost every province and territory. Walmart Canada’s network of warehouse and distribution centers keep these stores stocked with all the items Canadians need to “Save Money. Live Better.”

One important function of the retail warehousing and distribution is breakpack. Breakpack allows sending less than full case quantities to the individual stores. This is necessary to reduce the inventory carried at individual stores, resulting in significantly reducing the company’s overall cost of inventory. Breakpack items are typically slower movers and/or physically small items where a single case sent to an individual store would simply be much more inventory than the store needs.

Walmart Canada worked with MOSIMTEC to develop a simulation model to better understand the automated breakpack system. The modeling engagement resulted in several decisions on how to better utilize the new automation system. These insights had significant impact on the productivity of the system.

Challenge

Breakpack boxes sent to retail stores often contain very few batches of a unique SKU, along with a significant mix of other SKUs. The SKUs must be combined in such a way to reduce sorting and wasted travel at the store level, while still maximizing carton fill to reduce transportation costs from the DC to store.

Automation can be used to correctly present source containers to pickers to pick and place items into the breakpack containers sent to the store. Walmart Canada was already far along the design and implementation path for an automated breakpack solution, but realized they did not fully understand how to make optimal use of this solution on day 1 of go live. Walmart Canada did not want to spend weeks or months fine tuning best practices on a live system.

Solution

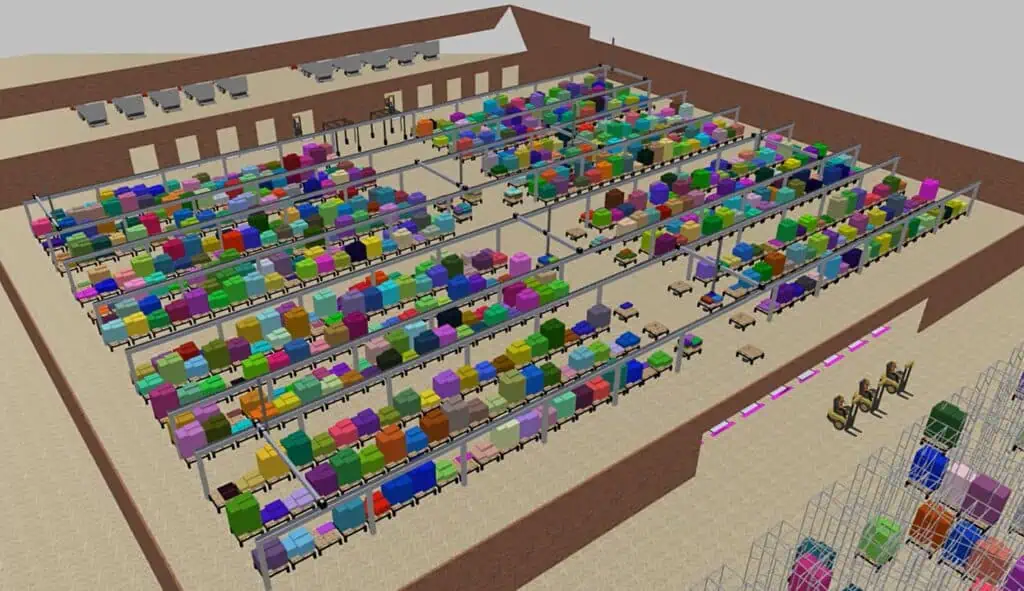

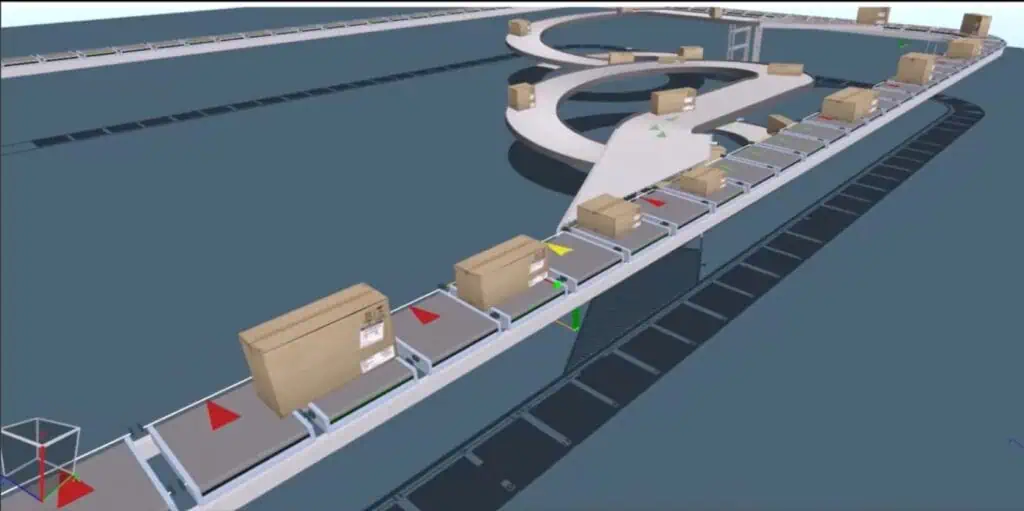

MOSIMTEC designed and developed a flexible, AnyLogic-based discrete-event simulation model to allow Walmart engineers to test the impact of storing various SKUs in the breakpack system’s automated storage and retrieval system (ASRS). The model allowed engineers to test a variety of demand patterns and various SKU profiles. The tool allowed Walmart Canada to seed the model with specific, historical SKU data and also examine profiles that may only exist in the future.

Benefits

With the model, Walmart Canada was able to quickly realize that previous perceptions regarding the system bottleneck were incorrect. Walmart engineers were able to consider how decanting operations may need to be offset from picking operations to alleviate the work load on the lift cells. A fundamental dynamic regarding empty bin turn-over patterns throughout the day was also uncovered, allowing engineers make recommendations in the managing of decanting.

The tool is also being used to understand the most attractive SKUs to send through a breakpack system versus a case pick system. The tool’s ability to measure ASRS utilization is key to understanding when additional SKUs can be converted to breakpack SKUs.

The dynamics discovered with the simulation model would have been difficult, if not impossible, to uncover with traditional spreadsheet modeling. Walmart Canada was able to understand system behavior months before go-live, so they could better plan the operational use of the new system without having to disrupt live operations.

More Information

Download a PDF: WalmartCanadaBreakpackCaseStudy

Contact MOSIMTEC to learn more about developing models for your business.

MOSIMTEC’s core focus is assisting clients make better decisions through application of decision support tools. Our team has extensive experience working with leading computer simulation software and solving complex issues for clients across various industries.

Other Case Studies

- All

- 3D simulation

- AMR

- Anylogic

- automated mobile robots

- bottlenecks

- conveyor design and implementation

- conveyor physics engine

- Distribution Center

- Emulate3D

- Emulate3D 2024 User Group Meeting

- industrial automation

- Logistics

- material movement analysis and design

- Oil-and-Gas

- order fulfillment

- Rockwell Automation

- Simulation

- slugging options

- terminal simulation

- throughput validation