Your Facility Needs To Run Without Inefficiencies. Leverage Our Simulation Service To Optimize Your Manufacturing Systems.

Gain invaluable insight into how your manufacturing operations can be made more efficient. We will lend our years of expertise alongside powerful simulation tools to find the most profitable scenario for you.

Our lean manufacturing simulation software solutions:

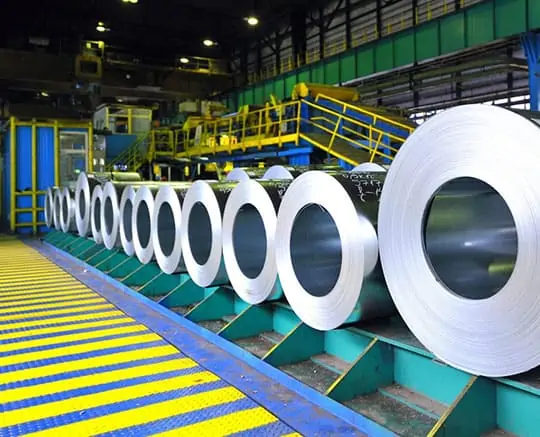

- Work for a wide range of businesses

- Provide powerful, actionable insights

- Optimize resource allocation

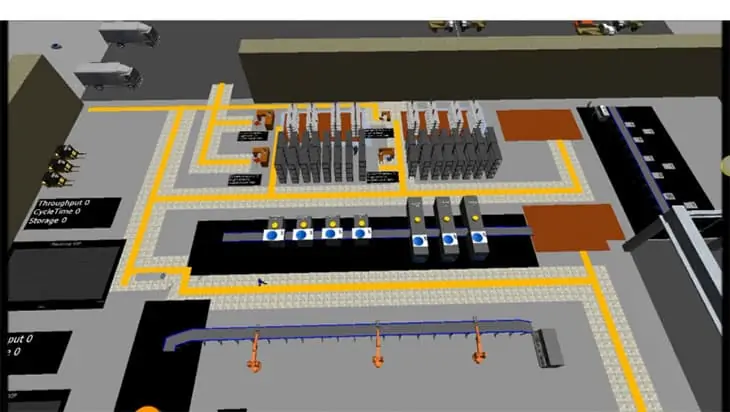

Simulation Software for Manufacturing

How we can help

- We will simulate your factory or production facility using 3D CAD drawings to optimize your layout.

- Communicate with all levels of the organization by using realistic 3D animation.

- Quantify resource utilization and optimal job assignments for your staff.

- Independently validate the design of your green-field investment.

- Compare your performance gains under a variety of operating scenarios.

- Experiment with various product mixes and volumes.

- Model new production processes to analyze a variety of impacts.

Why you need to use dynamic modeling & simulation?

Complexity

Complexity

There are too many factors and inter-dependencies that make it impossible to represent in a spreadsheet.

Variability

Variability

You are most likely designing for the worst-case scenario by over-capitalizing.

Our clients say

Success here will be exported throughout the world, changing perceptions, pioneering and opening new markets and saving lives. -DroneAmerica.com

MIKE RICHARDS

Simulation starts where Statistics ends…

BIG FOUR CONSULTING FIRM

Very hands on. You were very interactive and supportive of any questions that popped up during the course.

Pharmaceutical Automation Solutions Provider

The course provided a great overview of all the software as well as a good base to begin building models and refining our skills through repetition. It was exactly what I was looking for.

Deere & Company (John Deere)

We had a good time and learned a lot… Thanks for all your help.

National Institutes of Health (NIH)

Thank you guys for the extraordinary job! Very impressive.

Mining Corporation

Need to know what you are going to do, before you do what you are going to do.

Class I Rail Carrier

Commercial drones will change the way we do our jobs, improve our decision-making and save lives.

Jonathan Downey

Especially taking the variability into account… that’s phenomenal what you guys are doing.

Class I Rail Carrier

It’s the most advanced we’ve seen any customer.