Oil & Gas Simulation Software provides insight into throughput volumes, transit cycle times and costly bottlenecks in your system.

How Simulation Software helps the Oil & Gas Industry:

- On and off-shore oil extraction and production companies

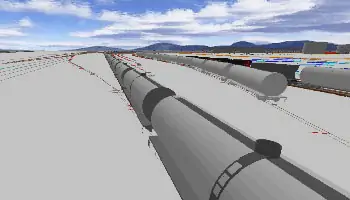

- Midstream service providers including rail, truck and pipeline operators

- Refineries, processing companies and export terminals

Oil & Gas Process Simulation Software

scheduling

Upstream

Midstream

Downstream

Why you need to use dynamic oil & gas process simulation software?

Complexity

Complexity

Too many factors and inter-dependencies make it impossible to represent all factors in a spreadsheet. For instance, a significant cost to upstream supply activity is the chartering and operating of an Offshore Service Vessel (OSV) / Platform Service Vessel (PSV). Oil and gas simulation modeling supports your decision-making, and help determine the best carrying capacity, total fleet capacity, and fleet configuration.

Variability

Variability

You are most likely designing for the worst-case scenario by over-capitalizing. Use oil and gas process simulation to decide where and when to invest in assets, schedule resources and identify bottlenecks to help you make an informed decision.

Simulating Offshore Operations

Evaluate trade-offs between business value and number of wells and equipment in a zone. Inspect the capacity constraints and infrastructure of the material handling system to quantify bottlenecks. Understand trends in transitioning from one drilling method to another.

Simulating Onshore Operations

Assess impact of speeding up one phase vs. another with the same number of equipment. Test different well advance limits. Understand financial implications of pulling forward high grade deposits as opposed to the executing the existing plan as-is.

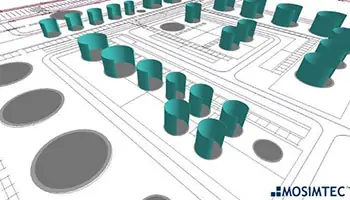

Optimizing Tank Farm Utilization

Study the influence of blending methods on processing systems. Identify future constraints that help or hurt recovery and throughput . Measure bearing of capital investment and utilization on cash – e.g. capital spent on network.

Oil & Gas Facility Maintenance Simulation

Analyze the impact of changes in availability as a result of different maintenance strategies e.g. opportunistic maintenance vs planned maintenance. We can identify the benefits and penalties of changes to MTBF and MTTR as well as asset replacement decisions.

Material Handling Up, Mid & Downstream

Oil and gas process simulation software can forecast the entire field-to refinery operation, including the multimodal transportation, product storages, transshipments, port operations. This integrated view helps identify local and global risk, and it enables a scientific way to evaluate process improvement programs.

Optimizing Tug and Barge Operations

Predict cycle times, throughput and mobile asset utilization in a digital environment. Incorporate scheduling and route constraints and business rules to validate barge operations down to a small variance from the real operations.

Our clients say

Success here will be exported throughout the world, changing perceptions, pioneering and opening new markets and saving lives. -DroneAmerica.com

MIKE RICHARDS

Simulation starts where Statistics ends…

BIG FOUR CONSULTING FIRM

Very hands on. You were very interactive and supportive of any questions that popped up during the course.

Pharmaceutical Automation Solutions Provider

The course provided a great overview of all the software as well as a good base to begin building models and refining our skills through repetition. It was exactly what I was looking for.

Deere & Company (John Deere)

We had a good time and learned a lot… Thanks for all your help.

National Institutes of Health (NIH)

Thank you guys for the extraordinary job! Very impressive.

Mining Corporation

Need to know what you are going to do, before you do what you are going to do.

Class I Rail Carrier

Commercial drones will change the way we do our jobs, improve our decision-making and save lives.

Jonathan Downey

Especially taking the variability into account… that’s phenomenal what you guys are doing.

Class I Rail Carrier

It’s the most advanced we’ve seen any customer.