A simulation is a replication of a real-world process or event in an environment that is isolated or disconnected from its real-world counterpart.

This concept is best understood with an example: imagine building a model of how a day at a retail store pans out. You construct rules for how people will interact, when supplies are delivered, ‘rush hour,’ ‘downtime,’ and whatever else to build an accurate model of that real-world retail site.

You will then run that model, typically in simulation software, to see the results of implementing those rules against variables, such as a late supply shipment or a Black Friday surge.

There are primarily three situations in which you would want to use simulation models:

- When you lack data, which is common when studying ancient or historical events.

- When your business processes are too complex to be analyzed through traditional methods

- When you need to experiment in a low-cost, low-risk environment. (if for example, you want to implement a risky, expensive change to your business, and need to validate).

Those situations appear self-explanatory, but there are deeper-level business advantages to running a simulation model, which we explore in detail below.

Business Competitive Advantages of Simulation:

1. Flexibility

You can simulate many different things. From business operations to training aircraft pilots, there is no shortage of existing and potential applications for simulation systems.

When it comes to simulation for business (e.g., the retail example provided above), you can employ it to capture insights in mining, manufacturing, retail, supply chain management, logistics, and many others. It’s industry agnostic and applicable to countless use-cases.

2. Test Large and/or Complex Systems

If you have enough computing power, you can simulate incredibly complex scenarios, such as the daily operations of an airport through an entire quarter or a city traffic grid.

It doesn’t matter how many rules you insert or variables you throw at the system. As long as you have the requisite computing power, you can simulate it with relative ease.

Presently, simulating large-scale environments, such as airports, is the norm. The difference actually lies in how to model and analyze simulations, not the concept of simulation modeling itself.

3. Isolated from the Real World Counterpart

With simulation modeling, you can generate copious amounts of insights without ever touching the real-world system.

This is a significant benefit for large-scale environments.

Be it airports, mining operations, global shipping and distribution activities, or aircraft assembly, all of these are multi-billion-dollar operations.

Inserting even one change in a complex, large-scale process can result in delays and quality assurance problems to the tune of tens or hundreds of millions of dollars.

With simulation, you can field-test your changes before they are implemented in the real world. You can get insights about potential risks beforehand, and prepare for them.

Take, for example, closing a road: yes, it will cause a bottleneck, but with simulation, you will know when that bottleneck will be most severe. You can tell construction crews to not be in the area during rush hour (so as to make it easier for traffic to flow).

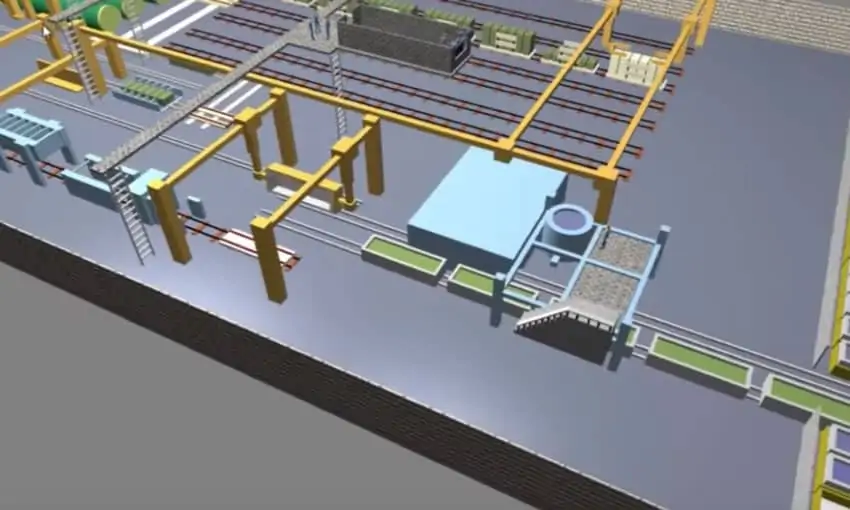

(Source: AnyLogic)

See How Fortune 500 Companies Got Ahead

with Simulation Modeling

4. Address Theoretical, “What-if” Questions

Whether it’s better understanding ancient civilizations or building-up business intelligence, you can also use simulation modeling to generate insights for their own sake.

The data may be inapplicable today, but it could be relevant in the future when the right factors (e.g., technology, regulatory environment, etc) materialize.

5. Study the Impact of Different, Interrelated Variables

It’s common for complex operations to involve many different factors.

In manufacturing, for example, you depend on hundreds or thousands of machines, a logistics chain, suppliers, access to materials, and human labor.

With simulation modeling, you can acquire an understanding of how your manufacturing operations will be affected as a result of a variable, such as bad weather, a worker strike, a political crisis in a country that supplies raw materials, and others.

This is valuable information for decision-makers, executives, and shareholders who are examining project proposals and changes to their existing systems.

For More on How Simulation Modeling Helps Businesses:

- Digital Twin: A Digital Replica of Your Business

- Better Staffing Through Simulation

- Alphabot: A Case Study In Use Of Simulation For Product Feasibility Analysis

6. Time Compression

Though you want insights spanning months or years into the future, you cannot afford to wait that long to get them. With simulation modeling, you can acquire information about the long-term — e.g., 12 months — relatively quickly, e.g., within 1 day.

For example, Texas A&M researchers recently simulated the potential of biomass growth in cool seasons.

7. Test for Complications

Be it the induction of a new machine in a factory or a new administrative process, you can test to see if it works as intended through simulation modeling.

In addition, you can identify potential complications and incorporate solutions for those (and test again) before implementing your change in the real world.

As you can see, simulation modeling provides a wide range of business benefits. If it can be summarized into one idea, it would be that of objectively predicting the results of your actions before they happen in the real world. ‘20:20’ awareness isn’t limited to just hindsight.

At MOSIMTEC, we’ve provided our Fortune 500 clients with actionable knowledge for lowering costs and increasing profit through simulation and modeling. Contact us today to discuss how you can leverage our resources to improve your bottom-line.