Opinion: Digital Twins (DT) has more to it than just 3D representation

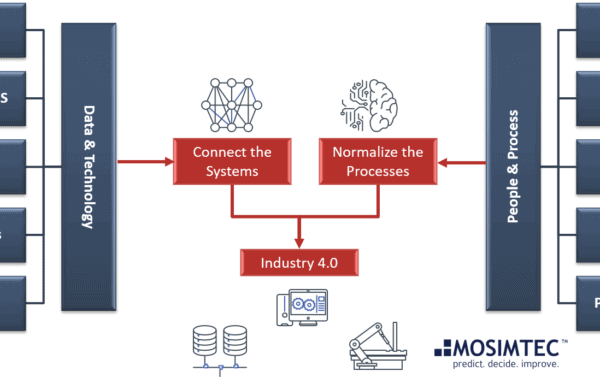

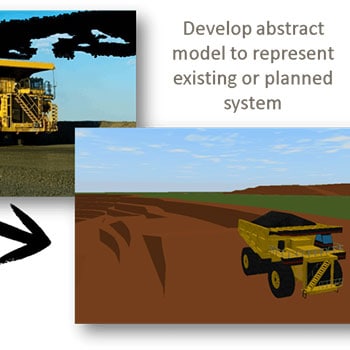

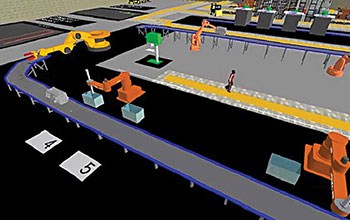

Digital twins (DT), virtual representations of the real world, are going mainstream in all shapes and forms. NVIDIA and Amazon Web Services (AWS) now offer simulation engines that allow businesses to build 3D…