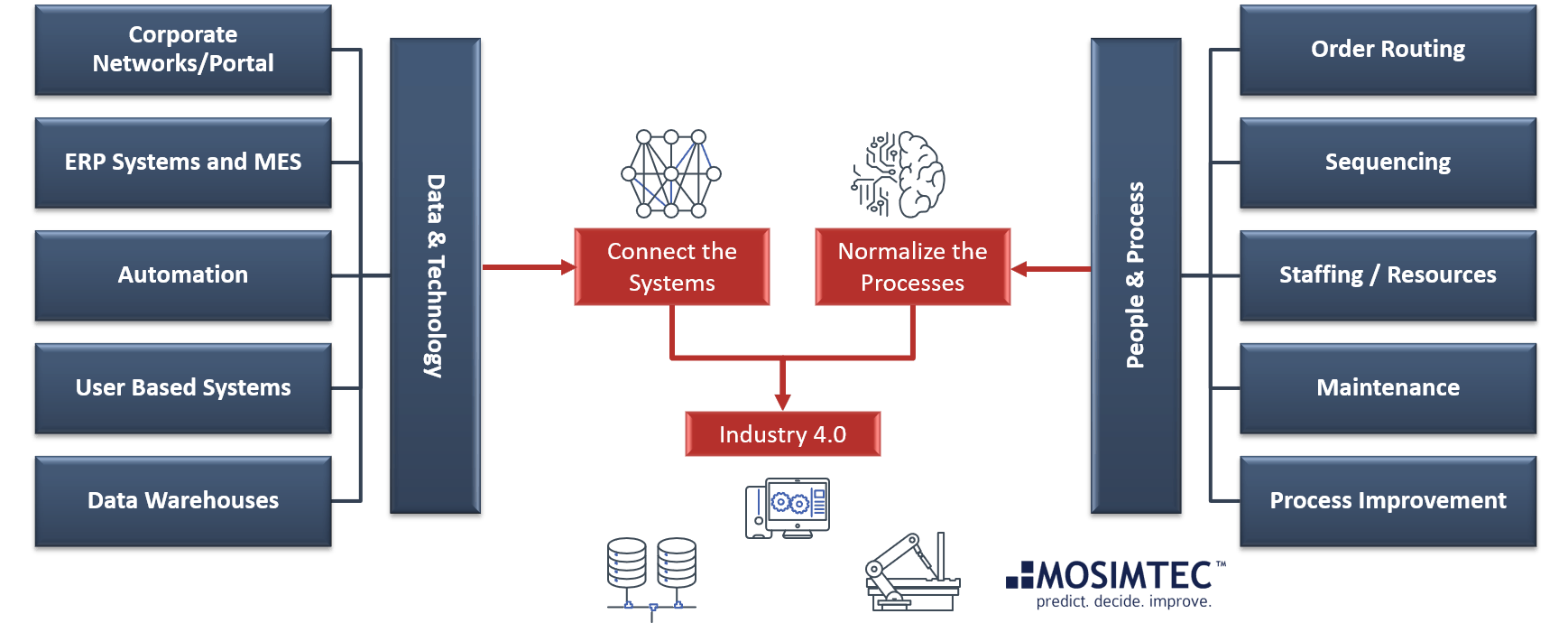

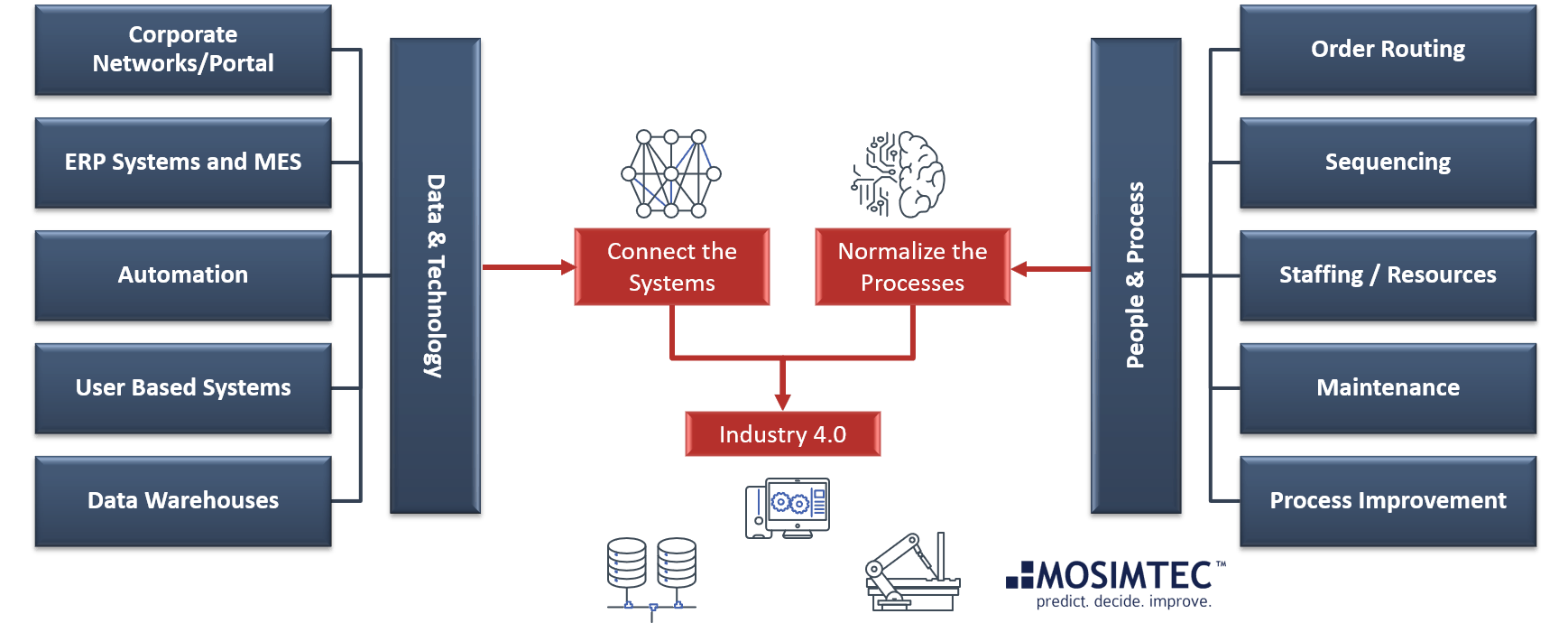

Simulation/Digital Twins are a pillar of Industry 4.0. A Digital Twin (DT) is a virtual simulation of a real world machine, product, process or system based on sensor data or other data sources.

Per SAP, this “enables businesses to better understand, analyze, and improve the performance and maintenance of industrial systems and products. An asset operator, for example, can use a DT to identify a specific malfunctioning part, predict potential issues, and improve uptime.” Digital Twins support analytics and digital connectivity core to Industry 4.0 and evolution to smart factories, warehouses and logistics, while enhancing visibility, sequencing and management of workflow to spark dramatic performance gains.

MOSIMTEC specializes in model development, simulation consulting and Digital Twin software. We put DT strategies to work for customers and work with clients to build a “focused” or “whole system” model of their enterprise by employing multiple modeling paradigms like agent-based, discrete-event and system dynamics. These models abstract out key aspects of the business while black-boxing other components providing toggles to construct different scenarios. If you want to leverage DT strategies for “next level performance”, MOSIMTEC can help.

#modelingandsimulation #digitaltwin #industry40