As global competition intensifies, the mining industry faces more and more challenges with every passing decade. Decision makers are called upon to reduce operational costs and improve profitability, external factors be damned. On top of that, the complexity of mining operations means that there are no guarantees that your mining project will get off the ground in the first place.

A big factor of failed mining operations is government regulations. In fact, regulatory risk was identified by EY as one of the nine major reasons why mining operations fail to be successful.

Getting Started with Government Mining Regulations

There is a complex array of government regulations in the United States that affect mining operations. Decision makers must be aware of each and every policy, as the consequences for failing compliance can be severe.

“Regulatory approval has become a major issue, and more than one high-profile project has failed to get off the ground due to delayed or denied permits, in some cases, costing the owners hundreds of millions of dollars.” – KPMG.

Mining organizations must stay on the ball, as it typically takes 7 to 10 years to get the permits necessary for a new mine in the U.S. Additionally, organizations must communicate with multiple government agencies such as the Bureau of Land Management (BLM) and the United States Environmental Protection Agency (EPA).

Don’t let compliance issues shut down your mining operation.

To help you, we’ve compiled the top 10 U.S. government mining regulations that you need to be aware of, and suggestions on how to increase your project efficiency while remaining compliant

Mining Government Regulations List

1. National Environmental Policy Act (NEPA)

Since January 1, 1970, NEPA has become a standard for environmental policy that has since been copied by over 100 nations around the world.

NEPA defines the “exact processes for evaluating and communicating the environmental consequences of federal decisions and actions.” This includes the guidelines for permitting the development of a new mine on any federal land.

For mining organizations, this means that any mine that is established on federal land must adhere to NEPA.

How Mining Simulation Can Help

The severity of failed compliance cannot be understated. Mining projects that fail to meet these stringent requirements are headed towards failure. Simulation is the key to meeting compliance requirements and mitigating any compliance risk.

The exact guidelines defined by NEPA can be assessed to the letter with simulation. This allows mining organizations to prepare for these requirements in a cost-effective manner.

2. Clean Air Act

The Clean Air Act, also founded in 1970, regulates airborne emissions and contaminants with the goal to reduce air pollution.

Mining organizations must be aware of the mining-related situations covered by this environmental policy. This includes:

- Dust emissions

- Tailings disposal at impoundments

- Exhaust emissions (from heavy equipment and otherwise)

- Emissions from processing facilities, such as smelters

And this has been particularly effective! According to an EPA study, in 2010 alone, the Clean Air Act prevented 13 million lost workdays with improved worker productivity due to less air pollution.

How Mining Simulation Can Help

Mining operations must deal with numerous emission costs, whether it be break emissions from natural production process, smelters producing side gases (SO2), or any CO2 emissions.

With simulation, operations can gain full insight into the true impact of scrubbers and the individual costs that are associated with the project. Simulation can help run operations for up to 10 years to ensure maximum profitability.

Learn How Mining Simulation Can Help You Achieve Compliance

3. Resource Conservation and Recovery Act (RCRA)

The RCRA environmental policy revolves around preventing the release of any hazardous wastes into the environment. This includes rules for the management of any hazardous wastes, whether it be in generating them or their disposal.

However, mining solid wastes that are considered “high-volume and low-hazard” materials are exempt under the RCRA. Regulation of those wastes is now done at the State level.

Toxic Substances Control Act (TSCA)

The TSCA applies to any new and existing chemical substances.

For mining organizations, this act covers any chemicals or hazardous materials used in the act of processing ore. For example, this includes sodium cyanide solutions.

Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

The CERCLA includes any regulation of mining wastes that are excluded from the RCRA. Essentially, this act allows the U.S. government to clean up any site that is found to have an unremedied release of any hazardous materials.

CERCLA regulators can hold all parties responsible – i.e. any mining organization – so it is important to be aware of the regulations around handling hazardous regulations.

How Mining Simulation Can Help

At a high level, simulation can predict the recovery time under certain spill conditions. This includes the resources allocated to spill-cleanup impact operations, understanding which operations need to be shut down (temporarily or permanently), and an operation’s preparedness to answering a cleanup.

A key aspect of simulation modeling is being able to answer these questions in advance, so in the case of emergency, you aren’t scrambling for answers.

4. Clean Water Act and Safe Drinking Water Act

Both the Clean Water Act and Safe Drinking Water Act address issues of water pollution. Mining organizations must be aware of how these acts impact surface water quality and any underground injections made into aquifers.

The Clean Water Act, founded in 1972, establishes a basic structure for regulating any pollutant discharges into any body of water in the United States. It is governed by the EPA, who has the authority to implement any pollution control programs and water quality standards that impact any mining operation.

Likewise, the EPA also governs the Safe Drinking Water act that protects public drinking water supplies.

How Mining Simulation Can Help

A mining operation can only progress as fast as the mine can dewater, which includes extraction and dumping. The removed water must go somewhere, and hydrology models can be used to determine the exact change in underground water flow/locations.

Mine processing also require water sources, whether that be a local water source or the recycling of their own water. Choosing between these two options is significant, as it can be impacted by local water regulations and add to an operation’s costs.

Simulation modeling can be used to solve both situations. The former can include information such as inputs from hydrology models to analyze the business system, while for the latter, it can be used to understand and optimize the best choice for any specific operation.

5. Endangered Species Act (ESA)

This act sets the standards for protecting and recovering any endangered animals or plant life in the U.S. The ESA extends to the waters around the U.S. as well, in order to protect sea life such as whales. In the act’s 40 year history, it has supposedly saved the bald eagle and Stellar sea lion from extinction.

Mining organizations must be aware of the ESA, as it can be an extreme roadblock to any mining operations.

How Mining Simulation Can Help

Similar to air emissions, necessary treatment plants produce liquid emissions. Water treatment plants are a significant expense to any mining operation.

Simulation modeling can be used to determine how these plants fit into the mine system and the logistics supporting them.

6. State Government Regulations

Each individual state has their own air and water quality regulations that must be accounted for. And as mentioned above, the regulation of high-volume and low-hazardous waste is also regulated at a state level.

This can be complex for mining organizations that are operating all over the country, as each mining operation will have to adhere to the laws of their locality. This means that decision makers must be aware of certain regulations that may differ between the state.

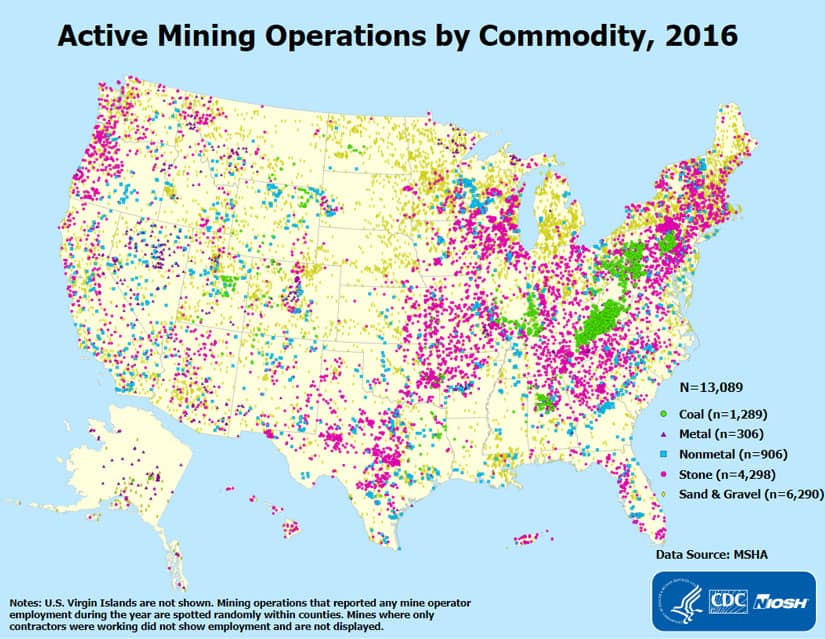

There are active mining operations in every state, as well as in the territory of Puerto Rico. Therefore, it is paramount that decision makers in mining organizations be aware of each individual states’ regulations around the operations.

Local and County Zoning Regulations

In addition to regulations at the state level, mining operations will have to be aware of any local county zoning regulations. This means that your relationship with the local government near your mining operation is of huge importance.

At this level, public input from local citizens should also be expected. Extensive public input in mining operations is part of the process to setting up your mining operation.

How Mining Simulation Can Help

An unfortunate aspect of permit applications is that the estimated permit start dates can be subject to change.

Simulation modeling can be used to determine when production might be impacted, and when to submit for a new zone, layback, or mine site permit.

7. Mine Safety and Health Administration (MSHA)

Mine safety legislation is enforced by the Federal Mine Safety and Health Act of 1977, which in turn was amended by the MINER Act of 2006. It is regulated by the Labor Department, with the Secretary of Labor having the authority to “develop, promulgate, and revise health and safety standards for the protection of life and prevention of injuries in the nation’s mines.”

The standards and regulations for mine safety – such as basic ventilation needs – is covered extensively by The Code of Federal Regulations (CFR).

8. Mine-Specific Emergency Response Plans

It is of vital importance that each mining operation have emergency response plans in place for that unique mining operation.

The U.S. Bureau of Mines focuses on research around mine emergency response in order aid both mine operators and safety professionals with best practices. Additionally, the National Institute for Occupational Safety and Health (NIOSH) through the CDC has published numerous studies around mine emergency response.

How Mining Simulation Can Help

Accidents, downtimes, and natural disasters such as earthquakes can have a severe impact on business cost.

Simulation modeling can help predict the cost of this downtime. By adopting simulation, you can see how your individual mining sites will be impacted by this downtime and discover the best methods for evacuation, attack, repair, or shutdown.

From Regulations to Mine Emergency Response Plans, Learn How Mining Simulation Can Perfect Your Strategy

9. Additional Standards to be Aware Of

Ultimately, those in charge of mining operations must be deeply intune with the complete array of regulations and standards that can impact their mining operation. After all, the documents that mining companies are required to produce cost millions of dollars and take several years to complete.

Mining decision makers should also be aware of standards such as:

- Environmental Impact Statements

- Feasibility Studies

Once all these documents that prove compliance for each and every one of these regulations and requirements are completed, scientists and technical experts should review all documents and data.

How Mining Simulation Can Help Assess Compliance

Achieving regulatory compliance is a daunting task and must be completed to perfection.

To truly understand the feasible mining and production rates in a dynamic system, while also abiding by any laws and environmental regulations, your mining operation will need more than just the status quo. Standard models – such as Excel – can lead to either being unnecessarily conservative or overly aggressive without knowing the true implications.

Here are some examples of what simulation modeling can predict for your mining operation:

- How and when equipment is used over time (i.e. haul trucks hours of operation and idle producing of C02);

- Conveyors consuming electricity;

- Chemical byproducts created by processing plants in continuous operation;

- Slurry pond sizing;

- And more, including how each of these is tied to business operations, such as revenue and cost.

All of this information – and more – must not only be gathered in order to acquire the necessary permits for mining operations within the U.S., but it also must be accurate.

Mining simulation can help save you millions in costs, and reduce the time it takes to get your mining project off the ground.

Learn More About Mining Simulation:

- The Most Important Operational Insights to Have on Your Mine

- Advice on Outsourcing Simulation Modeling

- Paris Agreement, Climate Change and Running a business: How computer simulations can help

At Mosimtec, we understand how important it is for your mining operation to comply with all sorts of regulations and environmental standards. Contact us today to learn how our mining business simulation models can aid you in meeting these rigorous standards.