Why Is Simulation-Based Planning & Scheduling Critical for Manufacturing and Other Industries?

The Reasons for Simulation-Based Planning and Scheduling

The manufacturing sector is undergoing multiple changes due to Industry 4.0, the COVID-19 pandemic, chip shortages, China’s COVID policies, and the Ukraine invasion. Industry 4.0 is bringing automation and computerization to the next level of the manufacturing execution system, through smart factories using advanced technologies. The pandemic and other events have led to supply chain disruptions and higher costs, leading to a shift away from globalization and towards more local and “just in case” approaches. The U.S. and Europe are bringing manufacturing jobs back home, and energy prices and incentives are favoring the U.S. The Russian invasion of Ukraine has also affected the manufacturing sector with many companies reviewing their production process. Effective Manufacturing Planning and Scheduling will play a crucial role in addressing the challenges and maintaining manufacturing excellence.

What is Manufacturing Planning and Scheduling?

Manufacturing Planning and Scheduling involves planning and controlling all aspects of manufacturing including managing materials; scheduling systems, machines, and people; coordinating with suppliers; and shipping to customers.

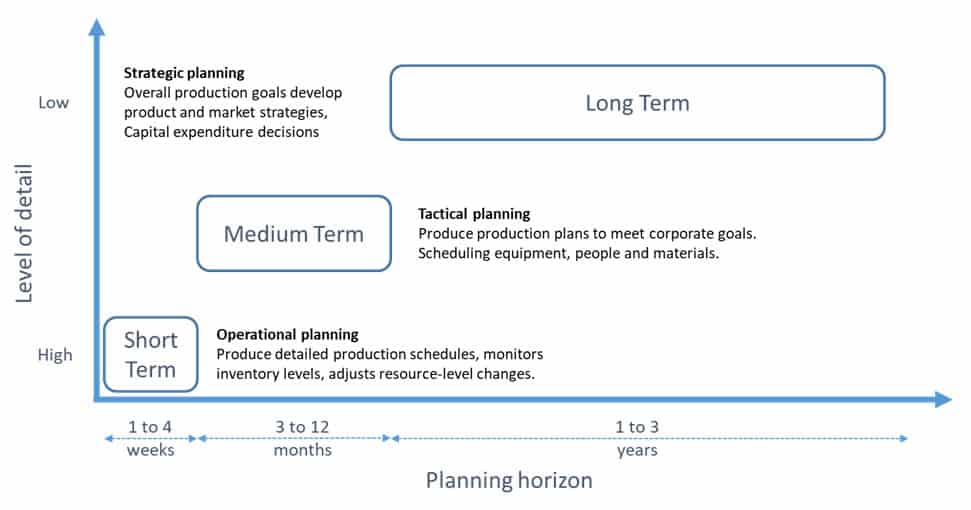

It addresses long-term needs of determining the appropriate amount of capacity to meet future market demands. In the medium term (master planning), the focus is on matching supply and demand for volume and product mix. In the short term (detailed planning), it involves developing a detailed schedule of resources such as time, people, materials, equipment, and facilities.

The three planning horizons of Manufacturing Planning and Scheduling include:

- Long-term planning horizon: This planning horizon typically covers a time frame of one to three years plus, and is focused on strategic planning for the manufacturing operation. This includes setting overall production goals, developing product and market strategies, and making decisions about capital investments, such as purchasing new equipment or expanding facilities.

- Medium-term planning horizon (also referred to as master planning): This planning horizon typically covers a time frame of three to twelve months, and is focused on tactical planning for the manufacturing operation. This includes developing production plans that support the overall production goals, scheduling resources and materials, and coordinating with suppliers and customers to ensure that everything is in place to meet production demand.

- Short-term planning horizon (also referred to as detailed planning): This planning horizon typically covers a time frame of one to four weeks, and is focused on operational planning for the manufacturing operation. This includes creating production schedules, monitoring inventory levels, adjusting production plans based on changes in demand or resource availability, and ensuring that all aspects of the production process are running smoothly and efficiently, in as much detail as possible.

Challenges with Planning and Scheduling

Planning and Scheduling in the manufacturing industry can be challenging for several reasons:

- Complexity: The more complex a project is, the more difficult it is to plan and schedule. For example, if a project involves multiple stakeholders, intricate tasks, and dependencies, it can be hard to ensure that everything is accounted for in the plan.

- Uncertainty: Uncertainty can make planning and scheduling difficult. For instance, if you are unsure of the resources required to complete a task, it can be hard to estimate how long it will take or how much it will cost.

- Human factors: Planning and scheduling often involve human factors, such as motivation, communication, and teamwork. These factors can be hard to predict or control, making it challenging to ensure that everyone is working together towards a common goal.

- Changes: Projects are dynamic, and changes can occur frequently. For example, stakeholders may change their requirements or timelines may shift. It can be difficult to adjust plans and schedules to accommodate these changes while still meeting project goals.

- Resource constraints: Resources, such as time, money, and personnel, are typically limited, and it can be hard to balance the competing demands of production management. For instance, if you have a tight deadline, you may have to sacrifice product quality or process scope to meet it.

Overall, Manufacturing Planning and Scheduling can be hard because it requires balancing many different factors and trade-offs, while also accounting for uncertainty and change in production processes.

How is Simulation-Based Planning & Scheduling Solution Better?

“Digital Twin” Simulations Make Planning and Scheduling More Effective

A simulation is an accurate abstract representation of a system that is typically connected to enterprise data (collectively also referred to as a “digital twin“). By collecting the current state of the system and the upcoming demand, decision-makers can use the simulation to forecast outcomes and plan accordingly. The simulation is run as quickly as computationally possible to collect detailed event logs, which represent the planned tasks, activities, and resource assignments that should be followed to replicate the desired outcome from the model.

Once the digital-twin simulation is complete, the resulting plan can be used to guide system operations in the real world. The plan can be rerun at a defined time interval or on a defined trigger to generate the new plan. By using this integrated simulation-based approach, manufacturers and production companies in other industries can gain greater visibility into their operations, make more informed decisions, and optimize their processes, thereby implementing the optimal solution for achieving better results.

Optimization vs Simulation-based Planning and Scheduling

Scheduling problems are among the hardest computational problems for which no practical optimal algorithms exist (mathematically classified as NP-Hard). Scheduling solutions make use of heuristics to generate a “good” solution. Two approaches to scheduling include optimization-based and simulation-based scheduling.

Optimization-based scheduling tools use mathematical constraints to generate a feasible schedule and then, by using a genetic algorithm, improve on it to get better system performance. These tools have limitations and work best in simple applications with few complex constraints. An example of optimization-based tool is Production Planning and Detailed Scheduling (PPDS) from SAP.

On the other hand, simulation-based planning and scheduling tools replace mathematical constraints with a computerized simulation model of the facility, generating schedules by simulating the flow of work through the model. Such simulation-based tools offer greater flexibility and transparency compared to optimization-based tools. The schedule is generated by applying heuristic scheduling rules in the decisions made during simulation and can be optimized by changing these rules.

Use for Operational Planning

Operational production planning simulations represent the next evolution of one-time design simulation models. Operational production planning simulations need to incorporate additional details like work-in-progress (WIP) inventory data as well as rules (for material allocation, for dispatching, for handling downtimes, for sequencing orders, and for other algorithms to automate human decision-making).

Operational planning simulations are required to generate detailed statistics and logs of events for the scheduling user to validate the model’s behavior. Once the operational simulation model generates a detailed and trustable schedule that can be implemented on the factory shop floor, it can be integrated with information technology (IT) systems for automated lights-out execution on a continuous basis.

Figure 2 illustrates the journey from Design simulation to a true Digital Twin of your business process:

How MOSIMTEC Helps Decision Makers With Planning and Scheduling

Data-Driven Production Planning and Scheduling Solutions

MOSIMTEC develops customized, software-generated, dynamic business simulations for data-driven decision-making that allows senior executives and shop-floor personnel 1) to see how different assets and processes impact each other and 2) to see how to make your systems work better. As a result, conducting further analysis of a MOSIMTEC virtual model (or “digital twin”) of your manufacturing production planning and scheduling systems is the best way for senior executives and ‘on-the-shop-floor’ operations teams to quickly re-plan when faced with new constraints to or changes in system performance.

How Can Simulation Models of Production Operations Help?

Some examples of factory-shop floor disruptions which MOSIMTEC’s operational digital-twin simulation can help plan for:

- Last-minute change in priorities, such as new orders

- Unexpected events, such as equipment breakdowns

- Changes in product mix or routings

Simulation can be a valuable tool for planning and scheduling by allowing you to model and test different scenarios to evaluate their outcomes and provide a feasible schedule. Here are some ways that simulation can help:

- Identifying potential bottlenecks: By simulating a project, you can identify potential bottlenecks or constraints that may impact its planning and scheduling. For example, you can see how increasing demand or limited resources might affect the timeline and make adjustments accordingly.

- Optimizing resource allocation: Simulation can help you determine the optimal allocation of resources, such as personnel or equipment, to complete tasks efficiently. You can test different scenarios to determine the best use of resources, allowing you to minimize costs and waste.

- Assessing risk: Simulation can help you assess risk by modeling different scenarios and evaluating the impact of potential risks. This can help you develop contingency plans or identify areas where additional risk mitigation strategies may be needed.

- Evaluating alternatives: Simulation can help you evaluate different alternatives and trade-offs to determine the best course of action. For example, you can compare the costs and benefits of different scheduling strategies to determine which is most effective for product quality and on-time delivery.

- Improving communication: Simulation can help improve communication between stakeholders by providing a visual representation of the project plan. This can help ensure that everyone has a clear understanding of the project goals and timeline.

Digital-twin simulation is a powerful tool that can aid in the planning and scheduling of a production process by providing a realistic representation of process requirements, enabling the testing of various scenarios and evaluating their potential outcomes. Using digital-twin simulation with as much detail as possible can result in more informed decision-making, as it allows for a quicker and more accurate assessment of operations.

MOSIMTEC Approach to Simulation-based Planning and Scheduling Project

The typical steps in creating and running a digital-twin simulation project are discussed in more detail.

- Measure twice, cut once. A simulation specification greatly reduces the time required for a simulation modeling engagement by ensuring the right model is built the first time. By thoroughly understanding the system and the questions the customer wants to answer, MOSIMTEC can ensure a model architecture is designed to meet those needs.

- The deliverable of this phase is typically a formal specification document that is updated in the future as the model evolves and can serve as a user’s reference guide.

- Most simulation projects fail due to a lack of adequate/successful specification phase. This phase includes:

- Articulating goals/objectives of the modeling effort.

- Ensuring adequate stakeholder buy-in and customer participation.

- Ensuring modelers adequately understand the system to be modeled.

- Defining data requirements.

- Designing model architecture and pseudo coding key functionality.

- Defining output metrics, the model must produce to meet goals/objectives.

- Defining validation approach/criteria.

- Defining model handoff/training expectations.

- MOSIMTEC utilizes good programming practices in developing simulation models. While this may seem like an obvious approach, many simulation consultants do not take the time to adequately plan and test their code, bringing in peers for brainstorming and code reviews along the way.

- Part of the MOSIMTEC approach to modeling includes building the model in phases. This allows the customer to see an end-to-end model functioning quickly. Details are added with each iteration, and the team can alter course as needed by taking smaller deliberate steps.

- Verification is the formal testing of the simulation model to ensure it adheres to the requirements and functionality described in the specification.

- Because MOSIMTEC focuses on a strong specification phase, the data requirements are known and provided to the customer before model development begins. This allows data collection and data transformation work to occur in parallel to model development. This may be done by the customer’s internal resources or by the MOSIMTEC team. If performed by the MOSIMTEC team, data is usually provided by the client and the transformation code / work is done by the MOSIMTEC team.

- Validation is the process of ensuring the model adequately mimics the actual system. While verification confirms the model behaves as the programmer intended, validation looks at holistic results and ensures that when the entire model ecosystem works together, it can accurately predict system behavior. The model ecosystem includes the model code, modeling assumptions, and input data.

- The goal of modeling is to have a model that is “accurate enough.” In some systems, this modeling may be successful if business decisions are better than using previous spreadsheets. In other systems, the team may want a model that accurately predicts the timing of order X within +/- Y hours or minutes. The desired/required accuracy is discussed during the specification phase and the actual accuracy is measured/estimated during the validation phase.

- The validation approach is determined and documented during the specification phase. MOSIMTEC will advise the customer during specification as to what validation approaches work best for their given system and goals/objectives.

- Analysis provides the customer with insights from the Simulation-based Planning and Scheduling model. Analysis approaches may range from running a large optimization to find the best combination of inputs to workshops where the team explores how the system reacts to various changes.

- The value of “playing” with the model is often greatly underestimated. Via collaborate exploration, the analyst/modeler can start to ask questions they did not even know they had at the beginning of the modeling engagement.

- Further analysis and deep understanding standing of system behavior is often gained over the course of model development and validation. Frequently significant insights have been gained and communicated to the customer before the formal analysis phase has even begun.

- Insights gained from the modeling engagement need to be implemented to result in improved business performance.

- Some tools may be re-used annually, quarterly, or monthly as system conditions have changed and policies need to be revisited. Other tools may be used more frequently to determine operational policies/schedules for a specific workload and specific system conditions.

- This phase involves the customer using the tool to continue to make strategic, tactical, or operational decisions. Support typically includes formal training and handoff, as well as MOSIMTEC being available to answer questions and make small changes to the model to accommodate new situations.

How Do We Enable Smart Factory Planning and Scheduling?

About MOSIMTEC Digital Twin Simulations

MOSIMTEC Modeling and Simulation assists businesses of all sizes with creating, running, and performing analysis on Digital Twin simulation models that help decision-makers predict outcomes and decide on courses of action. The applications of Digital Twin simulations are numerous, including Simulation-based Planning and Scheduling solutions for the manufacturing industry and other production-oriented industries.

Digital Twin simulations developed by MOSIMTEC have the advantage of maximizing efficiency in your manufacturing execution system, using data-driven finite-capacity planning and scheduling solutions to integrate processes and determining the next right step to take. MOSIMTEC’s Digital Twin simulation approaches include Predictive Models, Business Operations Simulation, Risk Analysis Simulation, Agent-based Models, Discrete Event Simulation, and System Dynamics Simulation.

Work with MOSIMTEC toward improved optimization of your manufacturing or production process. Contact the MOSIMTEC team of data scientists and industrial engineers for an introductory consultation. Rely on Simulation-based Planning and Scheduling for the manufacturing industry.