(Source: DepositPhotos)

(Source: DepositPhotos)

In 2019, the demand for sustainable supply chains is at an all time high. There’s a growing global expectation to eliminate greenhouse emissions, reduce carbon footprints, and procure from ethical suppliers.

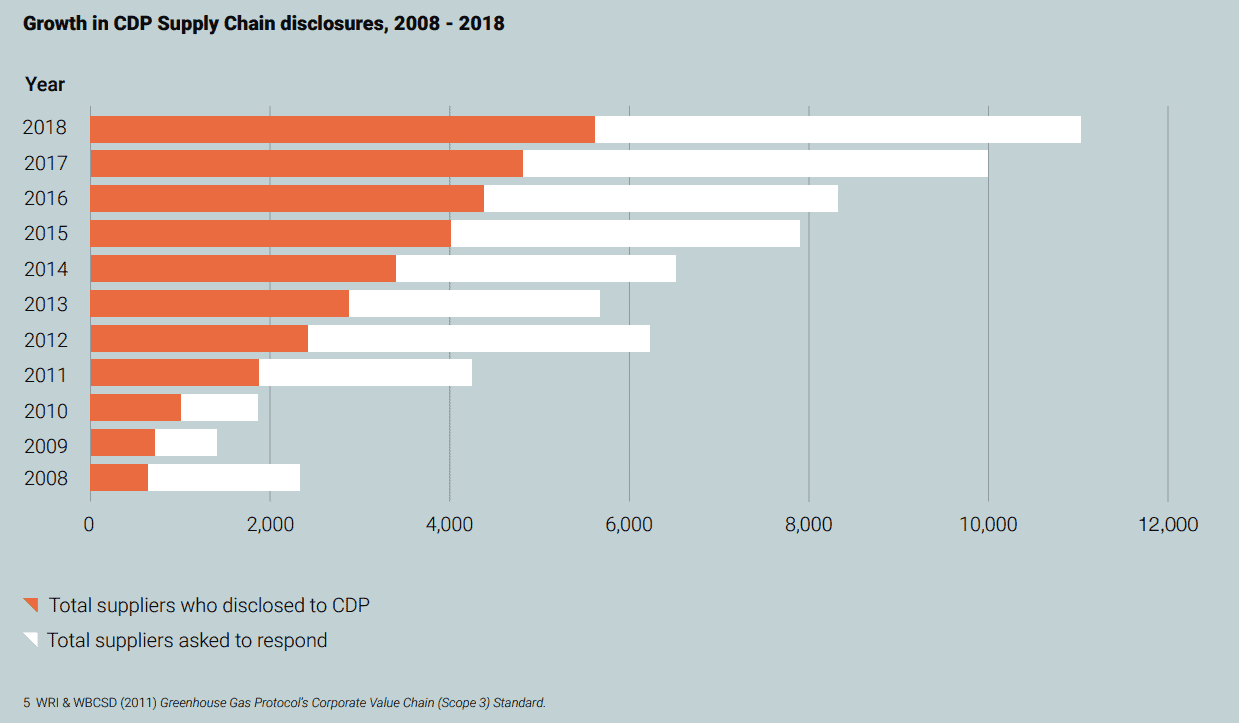

Recently, 115 of the world’s biggest procurers — collectively amounting to USD $3.3 trillion in purchasing power — took the first step in this regard by disclosing their suppliers through the Carbon Disclosure Project (CDP).

But the push for sustainable supply chains isn’t just limited to just addressing environmental, social, and economic issues.

There are strong business cases for doing so — like complying with regional laws, cutting resource waste, optimizing processes, and more.

Building sustainable supply chains is a growing priority for virtually all Western companies, and succeeding in this endeavor is not a trivial task.

In this post, we outline 3 essential steps you must employ when implementing your supply chain sustainability programs.

3 Essential Steps to Building a Sustainable Supply Chain

1. Get Full Visibility of Your Supply Chain

You will not get far in improving the sustainability of your supply chain without first acquiring full visibility of how it currently works. The CDP example noted above is the leading example of the world’s industry giants working towards getting that visibility.

You can acquire the necessary visibility by requiring your suppliers to disclose how they source, manufacture, and employ labor.

(Source: CDP)

You may also need to calculate your resource consumption via sustainability metrics, such as the carbon footprint, water footprint, and land footprint.

If you can’t source that knowledge in-house, you can partner with outside organizations that will both help steward your sustainability efforts and lend it outside credibility.

Waste is Sustainability and Profitability Problem

We Can Help You Remove It.

2. Partner with NGOs

In addition to lending credibility to your efforts, partnering with non-governmental organizations (NGOs) — such as the CDP — can also help you find inefficiencies in your supply chain.

How? Well, in many cases, the NGO might have a line of knowledge that your company doesn’t have. For example, Coke partnered with the World Wildlife Fund (WWF) to reduce the amount of water it used to produce a liter of Coke from 3 liters to 2.5 liters.

However, Coke did not internally know that it was spending 200+ liters of water in just growing sugar. The WWF identified the issue and suggested that Coke change how it grew sugar cane, so as a result, Coke managed to reduce its water usage (Harvard Business Review).

In terms of sustainable supply chains, such NGOs can help your business better understand its procurement from certain countries or suppliers. It can provide insight into the sustainability and ethical practices of those suppliers and, potentially, help you find alternatives.

As with Coke and WWF, NGOs can also help improve your supply chain processes with new or outside ideas. For example, having your supplies run through land could cost more in fuel than using freighters at sea — some NGOs can help find alternative routes.

More Insights on How to Improve Your Supply Chain:

- 7 Key Advantages of Simulation for Business

- 4 Agent Based Modeling and Simulation Examples

- 5 Types of Inventory Management to Get Your Expense Under Control

3. Identify Risks

To successfully implement sustainability, you must ensure that your proposed changes adhere to your industry’s regulatory rules and, not least, your business’ efficiency needs.

In terms of regulatory risks, you must review how your changes respond to the laws that affect your company. However, you will need to employ more tools to see the effect of those changes to your supply chain network and operations.

Simulation modeling is a preferred method to identifying risks in complex business systems.

Through a range of different data-based models, you can examine how proposed changes to your supply chain will impact your time-to-market, throughput, costs, and other factors.

Simulation modeling will enable you to identify risks and remove them before implementing your solutions, thus saving you from the real-world fall-out of those risks. For example, by changing a logistics route or raw materials supplier, you might see a new bottleneck in your processes.

Next Steps

As with most business processes, working towards a sustainable supply chain requires iteration and continuous improvement. Moreover, many businesses, including Fortune 500 companies, do not have the in-house tools and expertise to sustainably keep-up. However, that shouldn’t stop you — you can rely on outside firms with that capacity in parallel to your core efforts.

At MOSIMTEC, we help Fortune 500 businesses eliminate waste in their supply chains as a means for both achieving sustainability and stronger profits. Contact us today and set your business on the same track.